1. Introduction

In engineering construction, especially in fire protection and municipal construction, when pipes are often used, “ductile iron” pipes and covers are often used. Why not use other materials? To answer this question, let’s first understand what ductile iron is.

2. What is Ductile Iron?

Cast iron is an iron-carbon alloy with a carbon content greater than 2.11%. It is obtained by melting and casting industrial pig iron, scrap steel and other steel and alloy materials at high temperatures.

The chemical composition of ductile iron other than iron is usually: carbon content 3.0-4.0%, silicon content 1.8-3.2%, manganese, phosphorus, sulfur total not exceeding 3.0% and appropriate amounts of rare earth, magnesium and other spheroidizing elements.

3. Key Properties of Ductile Iron

– High strength: The tensile strength and yield strength are higher than those of ordinary cast iron, and it can partially replace cast steel and forged steel.

– Good toughness: Spheroidized graphite reduces the brittleness of the material, making it more tough and able to withstand larger impact loads.

– Good wear resistance: The wear resistance is better than that of ordinary cast iron, and it is suitable for occasions with harsh wear conditions.

– Good shock absorption: It has good shock absorption performance and can be used to manufacture parts that withstand vibration.

Due to the characteristics of medium-high strength, medium willfulness and plasticity, high comprehensive performance, good wear resistance and vibration absorption, and good casting process performance, ductile iron has been widely used in major industrial sectors, such as power machinery crankshafts, camshafts, connecting shafts, connecting rods, gears, clutch plates, hydraulic cylinders and other parts that are not often seen by ordinary people, as well as common manhole covers and fire water pipes are all ductile iron.

4. Ductile Iron Production Process

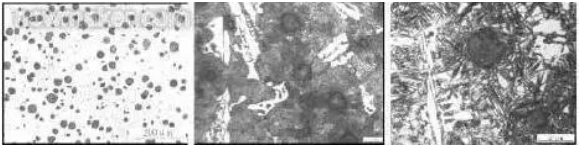

During the solidification process of molten iron, spheroidizing agents (such as magnesium, rare earth, etc.) are added to the molten iron to increase the number of graphite crystal cores and change the growth morphology from flake to spherical. At the same time, inoculants (such as ferrosilicon, etc.) are added to promote graphitization, reduce the tendency of white cast iron, and improve the quantity and quality of graphite balls.

Production process

– Melting: Use equipment such as cupolas and electric furnaces to put pig iron, scrap steel, recycled materials, etc. in a certain proportion, heat and melt, adjust the chemical composition, and make the molten iron reach the specified temperature and composition requirements.

– Spheroidizing treatment: When the temperature of the molten iron reaches the requirements, the spheroidizing agent is added to the molten iron ladle, and the spheroidizing treatment is carried out by flushing method, transfer method, etc. to spheroidize the graphite.

– Inoculation treatment: After spheroidizing treatment, inoculation treatment is immediately carried out, and inoculants are added to the molten iron to improve the roundness, distribution uniformity and quantity of graphite balls.

– Casting: Pour the treated molten iron into the pre-prepared casting mold, cool and solidify in the casting mold to form the required casting shape.

– Heat treatment: According to the performance requirements of the casting, ductile iron castings are subjected to heat treatments such as annealing, normalizing, quenching, and tempering to further improve their strength, toughness, wear resistance and other properties.

5. Ductile Iron vs. Gray Iron

1. The tensile strength of ductile iron is higher than gray cast iron and cast steel. If proper heat treatment is adopted, it can reach the level of forged carbon steel. And the tensile strength of ductile iron with the same composition can vary in a wide range (400-1500MPa) as long as different heat treatment processes are adopted.

2. Under the same tensile strength conditions, the yield strength of ductile iron is higher than that of steel. This is a very valuable performance of ductile iron as a structural material, and it is also one of the reasons why it is increasingly widely used as an important part of electromechanical products.

3. The elastic modulus of ductile iron is higher than that of gray cast iron, which means that its rigidity is greater than that of gray cast iron, but slightly lower than that of cast steel.

4. Although the impact toughness of ductile iron is not as good as that of cast steel, it is much higher than that of gray cast iron, and can meet the requirements of general working parts under dynamic loads.

5. The fatigue strength of ductile iron is more than twice that of gray cast iron, close to 45 steel, and because steel is more sensitive to notches than ductile iron, the fatigue strength decreases faster, so ductile iron can be used instead of steel to manufacture crankshafts and other complex parts.

6. Although the casting performance of ductile iron is worse than that of gray cast iron and it is prone to defects, its machinability is better, and the welding performance of ferritic ductile iron is also better. In addition, heat treatment can make the mechanical properties of ductile iron vary in a wide range. Under the same metallographic structure, heat-treated ductile iron has significant differences from cast ductile iron in some properties.

6. Applications of Ductile Iron

(I) Pressure pipes and accessories

Ductile iron is widely used as a material for pressure pipes and accessories in industrial countries. Ductile iron pipes have higher pressure resistance and can withstand greater internal pressure, ensuring safe and stable fluid transportation. Compared with traditional pipe materials, the construction of ductile iron pipes is more convenient and faster.According to statistics, in some large industrial projects, the installation time of ductile iron pipes can be shortened by more than 30% compared with traditional pipes.

(II) Automobile application

The high strength and good toughness of ductile iron enable automobile engines to withstand greater loads and impact forces when running at high speeds, ensuring the reliability and durability of the engine. In addition, the lightweight characteristics of ductile iron also help to reduce the overall weight of the car and improve fuel economy.

(III) Agricultural machinery and construction applications

In agricultural machinery, ductile iron parts can withstand the harsh field working environment, such as wear and impact of soil and sand. In construction projects, heavy equipment such as bulldozers and cranes require high-strength and high-toughness materials to ensure their safe operation. The excellent performance of ductile iron just meets these requirements, extending the service life of the equipment and reducing maintenance costs.

(IV) Valve manufacturing

Common ductile iron valves:

Gate valves: such as rising stem ductile iron soft-sealed gate valves, ductile iron elastic seat seal gate valves, etc., control the flow of media by rotating the valve core, with good sealing performance, and are widely used in industrial and municipal pipelines.

Ball valves: such as ductile iron eccentric semi-ball valves, PQ40F ductile iron eccentric semi-ball valves, etc., the ball rotates to open and close, with the advantages of small fluid resistance and reliable sealing, suitable for pipelines for conveying various media.

Check valve: It can prevent the backflow of media. It is often used in urban water supply systems and industrial fluid delivery system pipelines to protect equipment and pipelines from water hammer.

Butterfly valve: It is suitable for pipeline systems of water, gas, oil and other media.

Stop valve: It has good sealing and adjustment performance. It is often used in pipeline systems in chemical, food and beverage industries that require precise flow control.

7. Benefits of Using Ductile Iron

High strength and toughness: Ductile iron has higher tensile strength and yield strength than ordinary cast iron, and has good toughness, which enables the valve to withstand higher pressure and stress, reducing the risk of rupture or damage during use, and is suitable for various high-pressure and high-load working conditions.

Good wear resistance: Its wear resistance is better than ordinary cast iron. During the frequent opening and closing of the valve, it can effectively resist the wear of the valve sealing surface and valve seat by the medium, and extend the service life of the valve. It is particularly suitable for pipeline systems containing particulate matter or high-speed flowing media.

Corrosion resistance: Ductile iron has a certain degree of corrosion resistance, and performs well in some common media such as tap water, sewage, salt water, etc., which can prevent the valve from being corroded and affecting its performance and life. In addition, its corrosion resistance can be further improved through surface treatment, such as spraying anti-corrosion coatings, electroplating, etc., and can be used in corrosive environments such as chemical and marine.

Good shock absorption: Ductile iron has good shock absorption performance, can absorb and reduce vibration and noise in the pipeline system, make the valve run more smoothly, reduce noise pollution, improve the comfort of the working environment, and is suitable for valve installation near equipment with large vibration or pipeline system.

Good processing performance: Ductile iron has good processing performance and is easy to manufacture various complex valve structures, such as valve bodies, valve covers, valve stems and other components of gate valves, ball valves, butterfly valves, etc., which can meet different engineering design and use requirements, and the manufacturing cost is relatively low, which is conducive to large-scale production.

Strong designability: According to specific use requirements and working conditions, the performance of ductile iron can be optimized by adjusting the chemical composition and manufacturing process, such as improving strength, toughness, corrosion resistance, etc., to meet the special requirements of valve performance in different industries and projects.

Ductile iron also plays an important role in valve manufacturing. It performs well in transporting liquids such as acids, alkalis and salts. Ductile iron valves have good corrosion resistance and can effectively resist the erosion of various chemical substances. At the same time, ductile iron has good sealing properties, which can ensure that the valve does not leak when closed, ensuring the safety of fluid transportation. In some chemical, petroleum and other industries, ductile iron valves are widely used in pipeline systems.

8. Conclusion

Ductile iron castings are increasingly used in the manufacturing industry because they have the toughness and high strength of carbon steel and the rich graphite characteristics of cast iron, which can provide good lubrication. These excellent characteristics make them the darling of metal materials.