What is a Butterfly Valve?

Introduction

Butterfly valve, also known as flap valve, is a simple structure of the regulating valve, which can be used for the on/off control of low-pressure pipeline medium, and the butterfly valve refers to a kind of valve that rotates around the valve shaft to open and close the shut-off part (disc or butterfly plate) as a disc. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurries, oils, liquid metals and radioactive media. It mainly plays the role of cutting and throttling on the pipeline. The butterfly valve opening and closing part is a disc-shaped butterfly plate, which rotates around its own axis in the valve body, so as to achieve the purpose of opening and closing or adjusting.

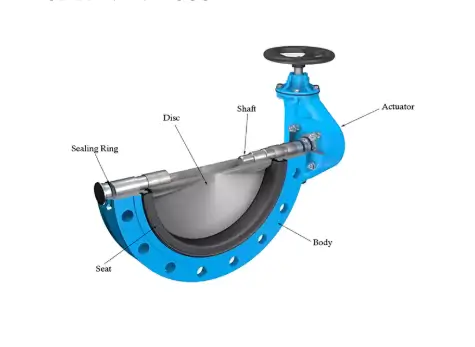

Butterfly valve parts

In order to understand the working principle of the butterfly valve, it is necessary to understand the structure of the valveThe butterfly valve is mainly composed of the valve body, butterfly plate, valve stem, sealing ring and transmission device. (1) Valve body: The valve body is cylindrical, and there is a cylindrical boss in the upper and lower parts for installing the valve stem. Butterfly valves and pipelines are mostly flanged connections; If the clamp connection is adopted, its structural length is the smallest. (2) Stem: The stem is the rotating shaft of the butterfly plate, and the shaft end adopts a stuffing box sealing structure to prevent the leakage of the medium. The upper end of the stem is directly connected to the transmission to transmit the torque. (3) Butterfly plate: The butterfly plate is the opening and closing part of the butterfly valve.

Types of butterfly valves

Butterfly valves are available in a variety of designs, each designed to meet specific performance requirements in different operations.

- Wafer Butterfly Valve The wafer butterfly valve is known for its slim design, which allows the device to be installed between two pipe flanges without the need for additional bolts. This butterfly valve is designed to be economical and can be used in a wide range of applications. The mezzanine design of the pinch valve allows the device to regulate the flow of fluid media and prevent backflow in the general flow system.

- Double Eccentric Butterfly Valve Unlike concentric valves, double eccentric butterfly valves deviate slightly from the centerline of the pipeline. Its stem does not cross the disc centerline, but flows around the disc centerline in the opposite direction of flow. This offset layout helps reduce seal wear and friction when opening or closing valves. Double eccentric butterfly valves are essential for systems that require a long service life, such as those dealing with viscous or abrasive fluids. They are also suitable for leak-proof performance in chemical processing, water treatment, and the oil and gas industry.

- Triple Eccentric Butterfly Valve As the name suggests, the triple eccentric butterfly valve is a unique type of valve that has three eccentricities, namely: the shaft, the seat, and the centerline of the seat. These three components form a tapered seat surface that provides all-metal sealed contact between the seat and disc. The unique design of the triple offset butterfly valve provides excellent sealing capability and ensures tight shut-off at high temperatures and pressures. Applications for these butterfly valves are most commonly found in places where high temperatures and pressures are frequently used, such as in the oil and gas industry and the petrochemical and refining industries.

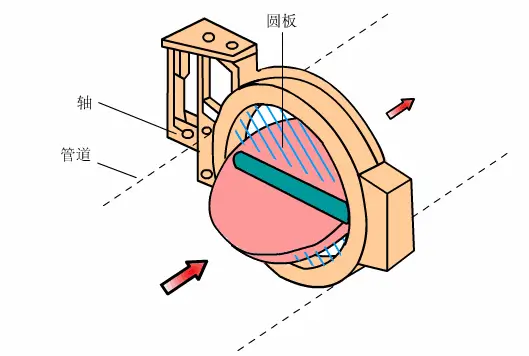

Butterfly valve: working principle

The opening and closing part of the butterfly valve is a butterfly plate, which is driven by the valve stem and rotates 90° around its own axis in the valve body to achieve the purpose of opening, closing or adjusting. It is mainly used to cut off media in pipelines. It has the characteristics of simple structure, flexible operation, fast switching, small size, short structure, small resistance and light weight.

Butterfly valve actuation

The electric butterfly valve is driven by electricity, which is composed of electric actuator and butterfly valve, so the temperature and pressure and climate are relatively low, but it is not suitable for working under wet working conditions. Pneumatic butterfly valve with compressed air as the driving force, is composed of pneumatic actuator and butterfly valve, relatively small size, light weight, when installing pneumatic butterfly valve, you can choose accessories, such as pressure reducing valve, solenoid, limit switch, etc…

1. Pneumatic butterfly valve is preferred under the condition of gas source, especially for the medium is combustible gas, and the gas can require rapid opening and closing of the valve ventilation butterfly valve. Pneumatic butterfly valve actuator can choose double-acting and single-acting, single-acting pneumatic valve, optional valve normally open or normally closed, when the air source is out of gas, the spring mechanism inside the actuator will automatically reset, so as to automatically open or close the valve, suitable for special safety requirements of high working conditions.

2. The electric butterfly valve has a large power torque, manual and electric dual-purpose operation, high degree of automation, and can be remotely controlled by the control box and PLC, and has been widely used in industrial pipeline control in chemical, metallurgical, petroleum and other industries.

3. Manual butterfly valve: Manual valves are operated by levers or handwheels, which are relatively simple and economical, but have a small range of frequent adjustments.

Advantages of butterfly valves

1. It is convenient and fast to open and close, labor-saving, and has low fluid resistance, and can be operated frequently;

2. Simple structure, small dimensions, short structural length, small size, light weight, suitable for large-diameter valves;

3. It can transport mud and accumulate the least liquid at the mouth of the pipeline;

4. Under low pressure, good sealing can be achieved;

5. Good adjustment performance;

6. When fully opened, the effective flow area of the valve seat channel is large, and the fluid resistance is small;

7. The opening and closing torque is small, because the butterfly plates on both sides of the rotating shaft are basically equal by the medium, and the direction of the torque is opposite, so the opening and closing is more labor-saving;

8. The sealing surface material is generally made of rubber and plastic, so the low-pressure sealing performance is good;

9. Easy installation;

10. The operation is flexible and labor-saving, and manual, electric, pneumatic and hydraulic methods can be selected.

Applications of butterfly valves

1. Industrial field In various industrial fields, butterfly valves are widely used. For example, in the petrochemical, water treatment, paper, food processing, pharmaceutical and other industries, butterfly valves are widely used as pipeline control and shut-off devices. In these industrial fields, because the types and properties of the medium are very different, the requirements for the material, sealing form, actuator and other aspects of the butterfly valve are also different. However, regardless of the application, butterfly valves must have reliable sealing performance, excellent corrosion resistance, high strength and consistent performance.

2. Construction In the construction field, the butterfly valve is also an important pipeline control and shut-off device. In construction, many different media are generally used, such as water, air, natural gas, etc. In order to ensure the smooth flow and stability of these media, various valves need to be installed in the pipeline. Butterfly valves are widely used in building piping systems because of their small size, light weight and easy operation.

3. Water treatment In the field of water treatment, butterfly valves are also one of the widely used valves. For example, in a water treatment plant, butterfly valves are used when water pipes need to be controlled and cut off to ensure safe and stable water quality. At the same time, in the field of gas and air conditioning, butterfly valve is also a widely used valve.

4. Hydropower In the field of hydroelectric power, butterfly valves are widely used in the control and cut-off of water turbine inlet and outlet pipelines. In hydroelectric power plants, the turbine generates electricity through a water flow generator, and the valves in the inlet and outlet pipes of the turbine, such as butterfly valves, play a role in controlling the water flow. Therefore, the quality and performance of butterfly valves are very important for the stable operation of hydroelectric power generation.

Principle of operation

When selecting a butterfly valve, factors such as material corrosion resistance, working pressure level, flange size and sealing performance should be considered to ensure long-term stable operation under specific working conditions. In summary, butterfly valves are an integral part of modern industrial piping systems, demonstrating superior performance and flexibility in a variety of fluid control scenarios. Understanding how it works and where it can be used helps us to make more effective use of this equipment and improve industrial productivity and safety.