Introduction

We occasionally see some relatively large valves in some pipelines, and bypass valves are always installed. Why is this? What is its main function? Under what circumstances do they need to be installed? And what is the size of the bypass valve of the corresponding equipment?

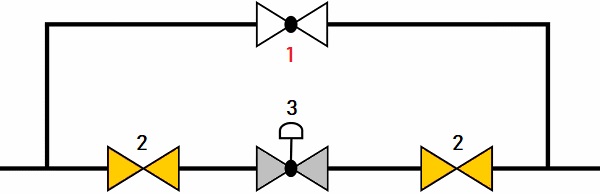

In fact, the role of setting a bypass valve in the pipeline can be generally divided into two major points: one is to play a protective role (balance the pressure at both ends), and the other is emergency backup!

1. Protection function: It can also be said to be a protection measure for the main valve to prevent the opening resistance from being large due to the large pressure difference before and after the valve, and the valve is difficult to open, especially in some large-diameter or high-pressure pipelines. Before the high-pressure pipeline is opened, the bypass valve is used to release the pressure to avoid the sudden influx of high pressure and the impact on the pipeline below the valve. Or the pressure difference at both ends of the valve is too large, and the opening torque is too large. In order to avoid torque damage to the valve, the bypass pressure is released before the valve is opened.

2. Emergency function: The biggest advantage of using it as a backup pipeline is that when the main valve fails or needs maintenance and repair, it can be circulated by opening the bypass valve without affecting normal production.

Specific requirements and settings for whether the valve needs to be installed with a bypass valve: (for reference only)

2.5MPa level, DN400 or above; 4.0MPa level, DN250 or above; 6.4MPa level, DN200 or above; 10MPa level, DN150 or above;

For valves of DN100~DN200, the bypass pipe and bypass valve are DN20; for valves of DN250~DN600, the bypass pipe and bypass valve are DN25; for valves above DN600, the bypass pipe and bypass valve are DN40.

Installation of differential pressure bypass valve

1. The differential pressure bypass valve should be loaded and unloaded carefully. It is recommended to use a soft rope to lift it to avoid damage to the valve and piping, protect the coating layer, and the valve should be carefully placed on the ground and cannot fall directly on the ground

2. Inspection before installation: After loading and unloading to the destination, first check and confirm according to the contents in the manual whether the piping is correct, whether the connection is reliable, whether the valve is damaged during transportation, and whether various parts are complete.

3. Before installation, clean up the debris in the pipeline, check the corresponding flange and the flange pressure level of the valve, and the nominal diameter is consistent to keep the pipeline unobstructed.

4. Two gate valves should be installed before and after the differential pressure balance valve for use during inspection and maintenance

5. The pressure sensing pipe of the differential pressure guide valve should be directly connected to the water supply and return pipes to accurately reflect the pressure difference between the supply and return. For the convenience of installation and use, a small ball valve can be installed on the sensing pipe.