The gate valve maintenance process generally includes the following steps:

1. Determine the work area:

Determine the work area and build a work platform to ensure the safety of the work area and take appropriate protective measures.

2. Close the valve:

Before closing the gate valve, you need to confirm whether there is fluid passing through to ensure the safety of the closing operation.

3. Emptying and decompression:

Drain the medium in the valve to ensure operational safety. If it is a high-pressure valve, pressure relief is also required.

4. Remove the bolts:

Use tools to remove the fixing bolts and remove the movable rod, gate and other parts connected to the valve body.

5. Repair parts:

Clean, inspect and measure the disassembled parts to confirm whether there are any damaged or worn parts that need to be repaired or replaced.

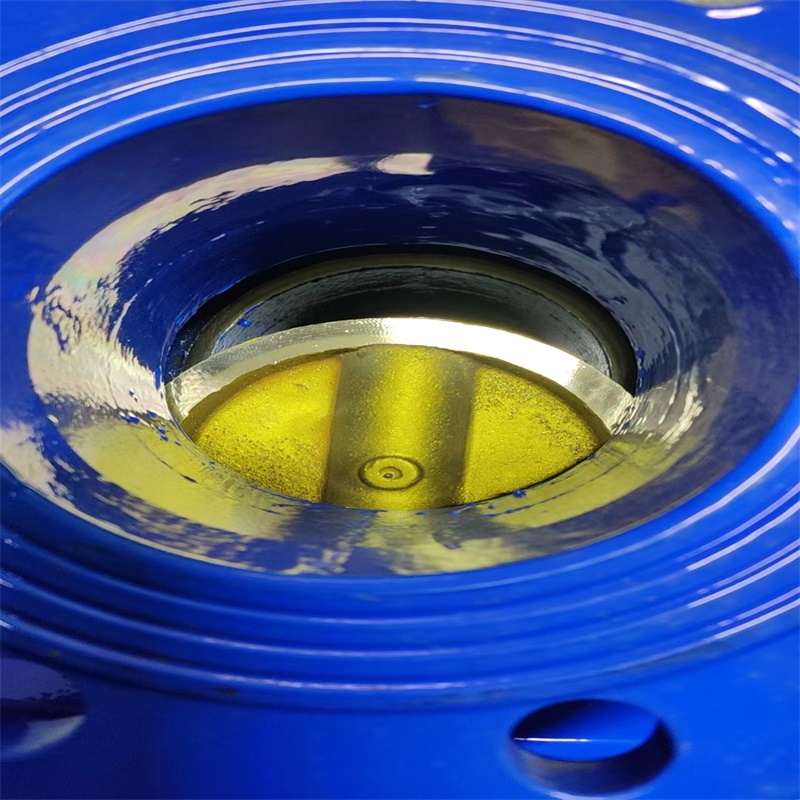

6. Check the valve seat seal:

Check whether the valve seat sealing surface is intact and repair it by grinding.

7. Lubrication and assembly:

Apply an appropriate amount of grease and assemble the relevant parts to ensure correct assembly.

8. Installation and debugging:

Assemble the assembled parts back into the valve body and perform debugging and testing as needed to ensure that the valve can open and close normally and can be effectively sealed.

9. Cleaning and tidying up:

Clean up the work area, including removing excess grease and waste, and organizing tools and equipment.

10. Write a report:

Based on the actual situation, write a maintenance work report, recording the problems found during the maintenance process, solutions and suggestions.

The above is the general process of Detsen gate valve maintenance. The specific operation needs to be adjusted and executed according to the specific gate valve model and working conditions. When performing the process operation, it is necessary to strictly follow the relevant safety operating procedures to ensure the safety of personnel and the normal operation of the valve.