The role of knife gate valves in wastewater networks

What is a knife gate valve?

Description

A knife gate valve is a valve specifically designed to handle fluids containing solids, similar to wastewater or sewage. It’s generally used in artificial channels and wastewater treatment installations.

Introductory function

Knife gate valve has a unique knife-shaped valve plate, which can fluently cut through solid patches or contaminations in the fluid to insure the smooth inflow of the fluid.

Applicable fields

In civic drainage systems, a knife gate valve can be used to control the discharge of sewage and rainwater and regulate the water position. It can open and close snappily with short response time, effectively precluding flooding and waterlogging. In addition, a knife gate valve can be used in sewage treatment shops to control the transportation and treatment of sludge.

In the paper industry, knife gate valves are generally used to control the inflow of pulp. As the pulp contains a large number of filaments and contaminations, ordinary valves are easy to clog, while the knife gate valve can effectively cut off the filaments and contaminations to insure the smooth inflow of pulp. In addition, a knife gate valve can also be used for paper wastewater treatment to control the discharge and recycling of wastewater.

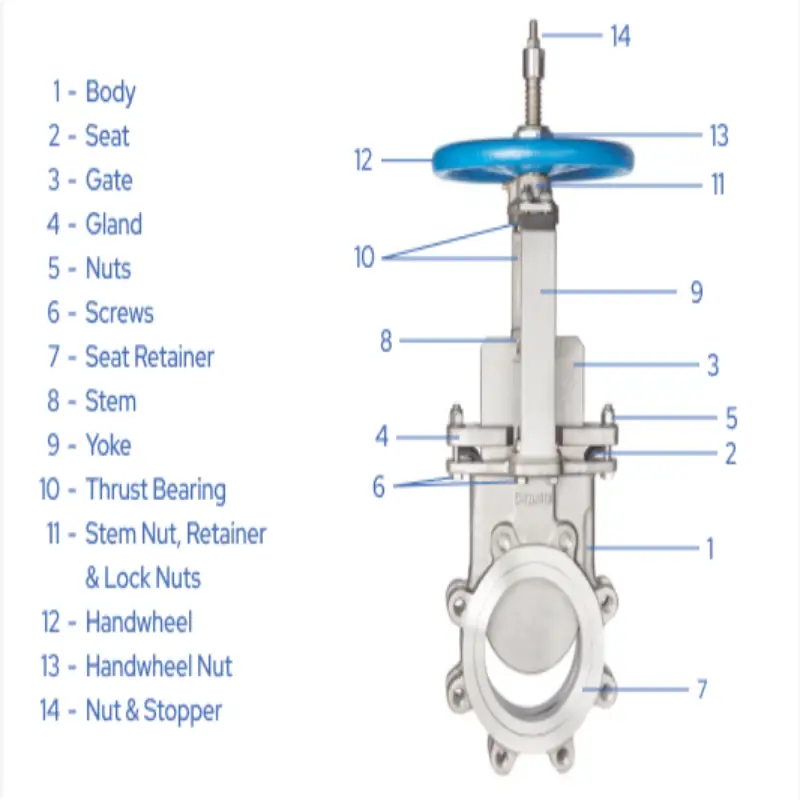

Design &corridor of a knife gate valve

The valve body: the body is the casing of the knife gate valve. The internal shape of the valve body is designed to match the channel of the gate so that the gate can move freely through it. The ends of the valve body are generally handed with flanged or threaded connection anchorages for connection to channels. Erosion-resistant accoutrements (e.g. cast iron, pristine sword) are generally used to acclimatize to harsh working conditions.

Knife-shaped valve plate: the gate is the core element of the knife gate valve, its shape is analogous to the shape of a knife, the bottom of the gate is scratched with a gash. The material of the gate plate is generally named according to the characteristics of the medium and the conditions of use,similar to carbon sword, pristine sword, amalgamation sword and so on.

Valve seat and sealing system: The sealing device includes the seat seal ring and quilting seal. Seat sealing ring is located between the valve body and the gate, used to insure the sealing performance of the valve. Seat seal ring material is generally rubber, PTFE, etc., with good pliantness and erosion resistance.

Quilting seal is used to fill the gap between the valve stem and the valve body to help media leakage. The material of the packing seal is generally graphite, asbestos, PTFE, etc., which has good sealing and erosion resistance.

Valve stem: the valve stem is used to connect the drive device and the gate plate to transfer the driving force so that the gate plate can move over and down to achieve the opening and closing of the valve. The material of the valve stem is generally pristine sword or amalgamation sword, with good strength and erosion resistance.

Driving System

The driving device can be named according to the factual requirements of homemade, electric, curvaceous, hydraulic and other driving styles to give power for the opening and ending of the valve.

Homemade drive device generally consists of handwheel, screw, etc., the operation is simple and accessible, but requires homemade operation, labour intensity.

Electric drive device consists of electric motor, reducer, coupling, etc., has the advantages of accessible operation and high degree of robotization, but requires power force.

Curvaceous drive device consists of cylinders, solenoid valve, gas source processor, etc., has the advantages of rapid-fire action, high reliability, but requires gas force.

Hydraulic drive device consists of hydraulic cylinders, hydraulic pumps, control valve, etc., with a large amount of force, the advantages of smooth movement, but need to supply a hydraulic source.

Working proposition of knife gate valve

Overview of the working principle: When the knife gate valve is in the open state, the knife plate rises and the fluid can flow in and out of the channel through the valve. When the valve needs to be closed, the control medium causes the knife plate to descend so that the knife plate connects the sealing face of the valve base, therefore fully cutting off the fluid in the channel.

Solid penetration function: When cutting off the fluid in the channel, an angle is formed between the knife plate and the sealing face of the valve base, so that the medium is cut off and squeezed out of the valve, therefore achieving the purpose of the valve to cut off the fluid.

Operation mode:it can be operated manually,pneumatically or electrically,counting on the movement of the valve stem to control the lifting and lowering of the valve plate.

Advantages of a knife gate valve

Suitable for fluids with a high solids content: the design of the knife gate valve makes it particularly suitable for fluids containing solid patches, similar to wastewater, sewage or slurries.

Cutting function: the knife-shaped design of the valve plate enables the knife gate valve to effectively cut through solid patches in the fluid, reducing the threat of blockage.

High sealing performance: knife gate valves have good sealing performance, indeed, under extreme working conditions, to maintain a good seal and help prevent leakage.

High erosion resistance: thanks to the choice of accoutrements(e.g. pristine sword or erosion-resistant blends), knife gate valves are resistant to chemicals and sharp liquids in wastewater.

Easy conservation: Compared to other types of valve, a knife gate valve has a simple design that makes conservation and drawing easier.

Operations in the sewage treatment industry

Wastewater treatment: Knife gate valves are extensively used in wastewater treatment plants to cut off and regulate the inflow of wastewater containing solids, especially in sedimentation tanks, aeration tanks, and sludge treatment equipment.

Wastewater operation: In artificial wastewater treatment systems, a knife gate valve can be used to isolate channels and help wastewater backflow or leakage.

Sludge treatment: In sludge dewatering and treatment installations, knife gate valves are used to control inflow and maintain stable system operation.

Discharge Channels: knife gate valves play a crucial part in wastewater and sewage discharge channels, helping to treat and discharge wastewater and avoid environmental pollution.

Working with other equipment: knife gate valve frequently works in conjunction with pumps, strainers, gates, and other equipment to complete the wastewater treatment and discharge process.

Material Selection for Knife Gate valve in Harsh surroundings

Erosion- resistant accoutrements:

Knife gate valves are needed to repel a variety of sharp media in sewage, wastewater and chemical treatment processes. Thus, the valve material selection is veritably important. Generally used erosion- resistant accoutrements include pristine sword, amalgamation sword, and cast iron. these accoutrements can repel chemicals and largely sharp liquids in the course of long-term use.

High-temperature resistant accoutrements:

For sewage treatment in high temperature surroundings, knife gate valve may bear the use of high-temperature resistant blends or essence accoutrements to insure that the valve can still work duly under extreme temperature conditions.

Wear- resistant accoutrements:

For running fluids containing large quantities of solid patches or abrasive substances, the valve plates and seats of knife gate valve are frequently made of wear and tear-resistant materials, similar to hardened stainless steel or composite coatings, to reduce wear and prolong service life.

Considerations for opting for accoutrements:

When opting for suitable accoutrements, it’s necessary to exhaustively consider factors similar as the cattiness of the fluid, temperature, pressure, and whether the fluid contains solid patches.