Recommended Opening for Valves: A Comprehensive Guide

What Does Valve Opening Mean?

- Between fully closed (0%) and fully open (100%).is the Valve Opening.

- The different angles at which the valve is opened will produce different resistance to the water flow, thus affecting the flow and pressure.

Why is Recommended Valve Opening Important?

- Different valves corresponding to the opening Angle is different, according to the production needs, choose the right Angle will extend the service life of the valve, the flow of water flow size.

- If the Angle is not correct, it will bring serious consequences such as cavitation, pressure drop and leakage.

Recommended Valve Opening Ranges

General Recommended Opening for Valves

- We usually recommend that customers keep the valve at 50% to 70%, which is an ideal range for most valves.

- In this range, it can not only delay the service life of the valve, improve the passing rate of the medium, but also ensure the stability of the pressure in the pipeline, thus saving energy.

Recommended Opening for Linear Characteristic Valves

- Some specific valves need to be kept between 40% and 60%.。

- Due to the particularity of the internal structure of these valves, it is not recommended to maintain a large Angle during continuous work, otherwise it will affect the service life of the valve, thereby disrupting the flow in the pipeline, resulting in a reduction in production efficiency.

Factors Determining Recommended Valve Opening

System Pressure and Flow Requirements

- According to the medium pressure in the pipeline, the valve of different materials is selected, and the opening Angle is selected according to the characteristics of the valve, so as to balance the pressure and stabilize the flow rate in the pipeline.

Fluid Characteristics

- According to the density, corrosiveness, compressibility and viscosity of the medium in the pipeline, the corresponding valve is selected and the valve is adjusted to the appropriate Angle.。

Pipeline Resistance

- The opening and closing of the valve will lead to the occurrence of the water hammer effect, especially when it is quickly closed, the water hammer effect is the most intense!

Safety Factors

- In chemical plants or other special application scenarios, valve safety is the most critical factor. It is not only necessary to consider the explosion-proof performance of the valve, but also to consider the installation of safety valves at key locations in the pipeline.

Economy

- As we all know, valves with excellent performance usually have an excessive premium. The valve that conforms to our pipeline condition is the best choice, with the most suitable opening Angle, not only can extend the service life, but also save a lot of money.。

Principles for Setting Recommended Valve Opening

Ensure Normal Operation of the Valve System

- Regardless of the type of valve or the location of the valve in the pipeline, these valves should maintain a consistent pressure level to stabilize pressure and flow and meet production requirements.。

Avoid Over-Adjustment

- Once the valve is adjusted to the most appropriate state, do not change at will. Reduce the disturbance in the pipeline due to valve changes. It can also reduce unnecessary valve wear.

Consider Long-Term Operation

- The long-term stability and reliability of the valve is the core of ensuring industrial safety, ensuring continuous operation, reducing maintenance costs, avoiding system failures, and directly affecting production efficiency and equipment life.

Optimize Performance Parameters

- Valve opening should be dynamically adjusted according to production needs, balance the interaction between pressure, temperature and flow, ensure parameter matching, avoid overpressure or flow fluctuations, and maintain stable operation.

Practical Applications and Precautions

Thermal Systems

- It is necessary to accurately adjust the Angle of the valve to slowly control the flow changes, and to monitor the pressure in the pipeline in real time to minimize frequent operations to reduce heat loss and pressure fluctuations.

Chemical Plant Production

- The precise control of pressure and temperature is the core of chemical reaction safety, while ensuring equipment stability and operator safety.

Water Supply Systems

- Managing water pressure and flow requires dynamically adjusting valve and pump speeds, along with real-time sensors to monitor cone effects and pipeline vibrations, optimize fluid distribution and reduce energy loss and structural fatigue risks

Maintenance and Replacement

- Check the valve for wear and leakage regularly, and maintain and replace the parts in time。

Valve Sizing and Flow Coefficient (Cv)

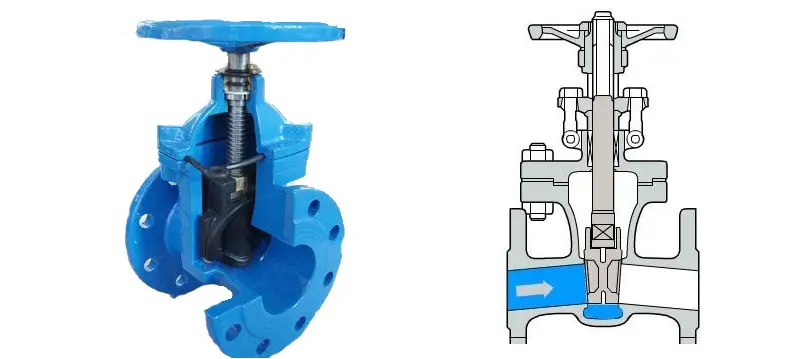

Importance of Correct Valve Sizing

- The appropriate size of the valve accurately matches the flow demand, avoiding too large (adjustment misalignment) or too small (pressure drop is too high), stabilizing the pressure distribution, reducing wear and energy consumption, improving the control accuracy and system life reliability.。

Calculating Downstream Pressure

- Downstream pressure formula: P2=P1−K⋅Q2 P_2 = P_1 −K \cdot Q^2 P2=P1−K⋅Q2 (K is the system resistance coefficient, Q is the flow rate). By dynamically adjusting the valve opening to control Q, to maintain the stability of P2, P2, P2, P2, to achieve accurate flow optimization, balance energy consumption and safety.

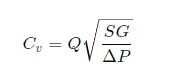

Using Flow Rate and Pressure to Determine Flow Coefficient (Cv)

Cv计算公式:

Q: Flow rate (unit: GPM, gallons per minute) SG: specific gravity of fluid (relative to water, dimensionless) ΔP: pressure difference at both ends of valve (unit: psi, pound force per square inch)

Function: Cv reflects valve flow capacity and is used to match system flow requirements and pressure drops, ensuring precise control and energy consumption optimization.

Selecting a Valve with Appropriate Cv

- Advise selecting a valve with a Cv slightly higher than calculated for smooth operation.

- When the valve Angle is about 70%, it is in the best state of performance. Then this valve is worth your choice.