Pneumatic butterfly valve is a common control equipment, widely used in industrial production. In order to ensure the normal operation of the pneumatic butterfly valve and extend the service life, it is necessary to carry out daily maintenance. The following is the daily maintenance manual of the pneumatic butterfly valve:

Regular cleaning:

Clean the pneumatic butterfly valve regularly to prevent the effect of ash and dirt on the valve. Wipe the outer surface of the valve with a soft cloth to remove dust and oil stains.

Regular lubrication:

According to the frequency of use and working conditions, regularly lubricate the pneumatic butterfly valve. Use the appropriate lubricant and follow the lubricant instructions for lubrication.

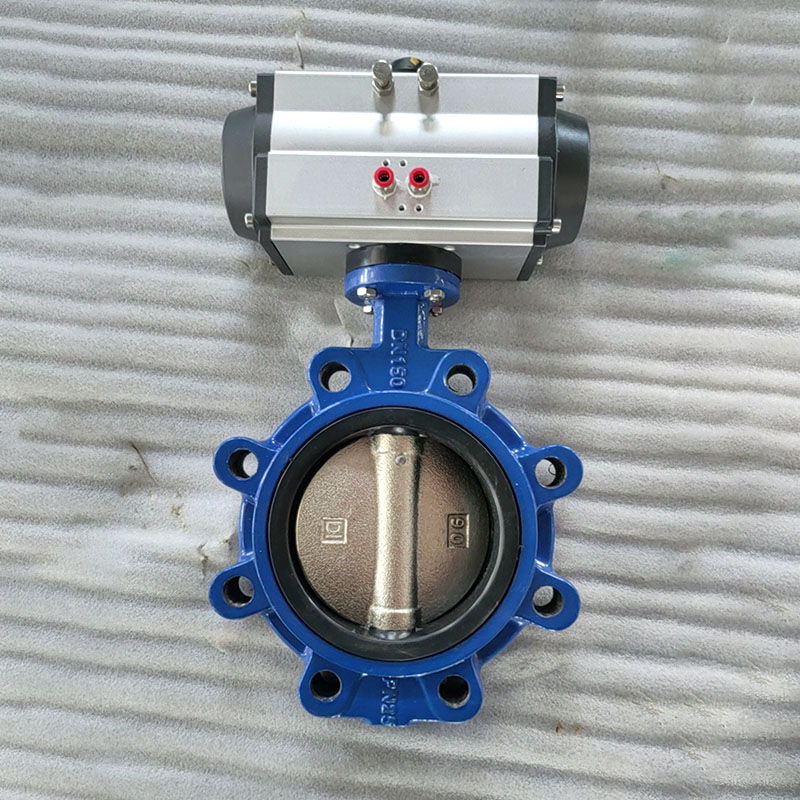

Check the tightness:

Check the sealing performance of the pneumatic butterfly valve regularly. After closing the valve, check whether there is leakage on the sealing surface. If there is leakage, it is necessary to replace the seal in time.

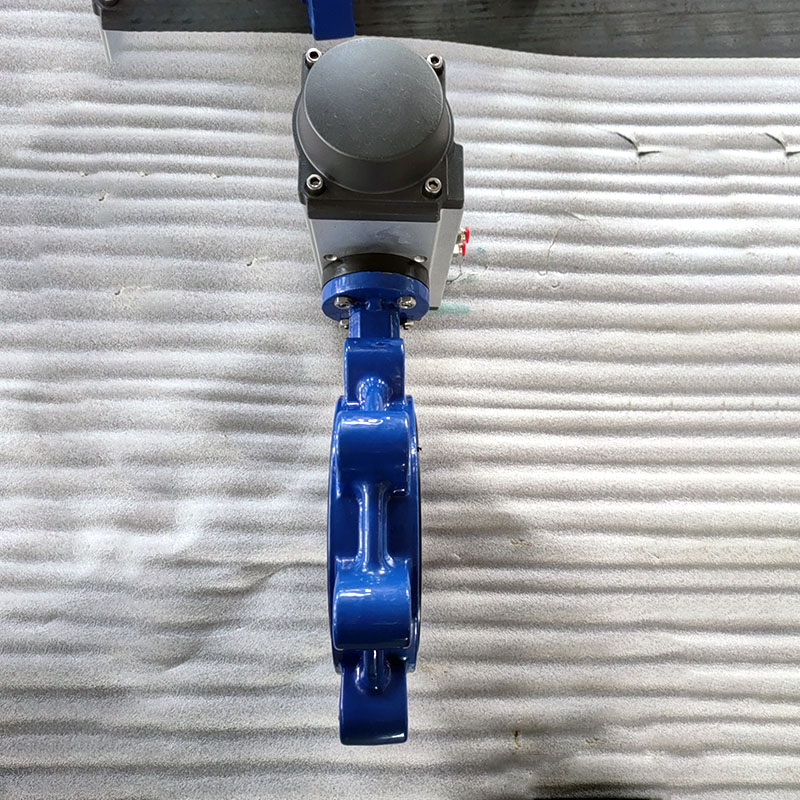

Check the connection:

Check the connecting parts of the pneumatic butterfly valve regularly to ensure that the connection is firm. Check whether bolts are loose. If they are loose, tighten them.

Inspection operation:

Check the operating performance of the pneumatic butterfly valve regularly. Check whether the operation of the handle or manual device is flexible and whether there is a blockage. If there is a problem, it should be repaired or replaced in time.

1. Check the pneumatic device:

Check the pneumatic device of the pneumatic butterfly valve regularly. Check whether the air source connection of the pneumatic device is normal and whether the work of the pneumatic actuator is normal. If you find problems, deal with them promptly.

Regular inspection:

Regularly ask professionals to perform maintenance, replace seals, lubricants and other work.

The above is the daily maintenance manual of the pneumatic butterfly valve, I hope it can help you. When performing maintenance, you must follow the operation rules to ensure safety.