Part One Introduction

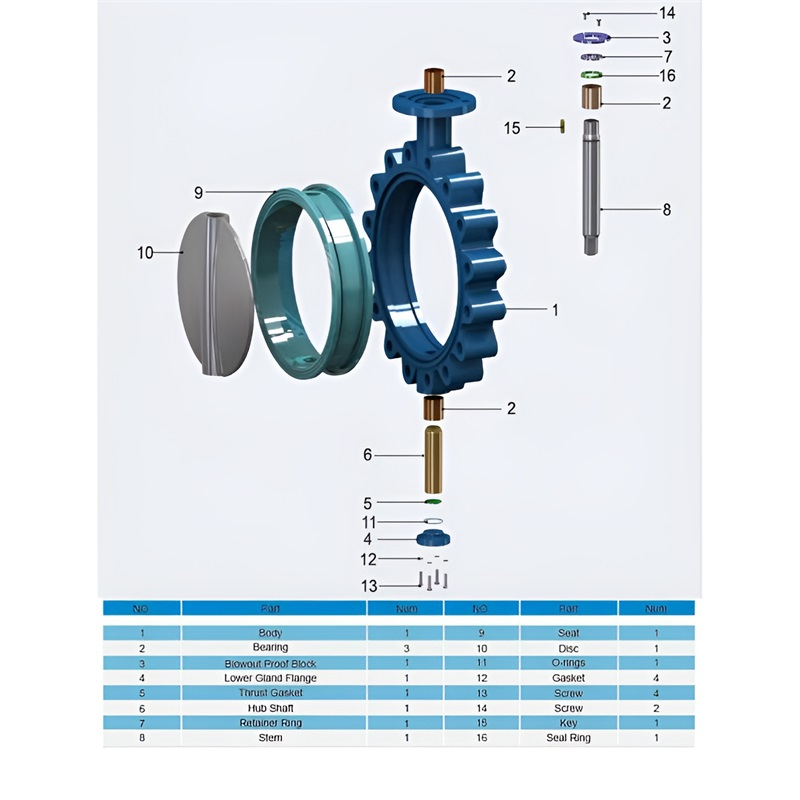

The lug type butterfly valve is mainly composed of a valve body, a valve bonnet, a valve stem, a plate, a sealing ring, etc. When the plate rotates around the axis in the valve body, the sealing ring will stick tightly to the plate, thereby realizing the opening and closing of the valve. The lug type butterfly valve has the advantages of simple structure, easy operation, good sealing performance, etc., so it has been widely used in the industrial field.

Part Two Structure

1、Seat Ring

The seat ring is one of the key components of the lug butterfly valve, located on the valve seat inside the valve body. Its main function is to provide a sealing effect, so that the valve can be quickly opened and closed during operation, and effectively control the opening and closing state of the fluid channel. The seat ring is usually made of highly wear-resistant materials, such as high-density polytetrafluoroethylene (PTFE), to ensure its durability and sealing.

2、Disc

The valve plate is the core component of the lug butterfly valve, which is responsible for controlling the opening and closing of the fluid channel. This component is made of a disc-shaped metal sheet, usually made of corrosion-resistant materials such as stainless steel.

3、Seals

The seal is an important component of the lug butterfly valve, which is used to prevent fluid leakage.

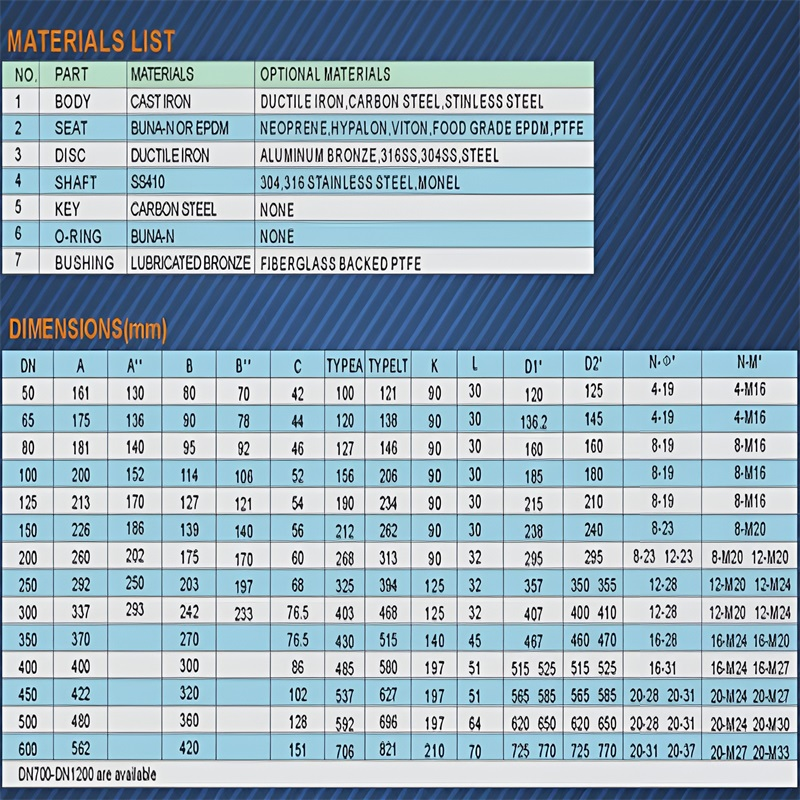

Part Three Technical Data

Part Four Features

1. Good sealing: Lug-type butterfly valves usually use sealing gaskets to ensure sealing. Some models also have a triple sealing structure (two layers of sealing and one layer of metal sealing), which can maintain good sealing performance under high temperature, high pressure and corrosive media.

2. Rapid opening and closing: The opening and closing of the lug-type butterfly valve is fast, which can quickly realize the on-off control of the medium and improve the operating efficiency of the pipeline system.

3. Strong corrosion resistance: The valve body and valve plate are made of various materials, such as stainless steel, which makes the lug-type butterfly valve have good corrosion resistance and can be used in a variety of media environments.

4. Easy to operate: The lug-type butterfly valve is easy to operate and easy to control. Some models are also equipped with reliable operating handles and electric devices to ensure precise control and convenient remote operation.

Part Five Applications

Lug-type butterfly valves are widely used in the industrial field, mainly in the following aspects:

1. Petrochemical industry: Lug-type butterfly valves are used in pipeline systems of petroleum and chemical industries as devices for regulating and cutting off media.

2. Metallurgical industry: Lug-type butterfly valves are used in heating furnaces, cooling furnaces and other equipment in the metallurgical industry as an important part of the fluid control system.

3. Power industry: Lug-type butterfly valves are used in power systems such as power plants and substations as key equipment for fluid control systems.

4. Water treatment: Lug-type butterfly valves are used in water treatment industries, such as sewage treatment plants and water plants, as key equipment for fluid control systems.