Butterfly valves are widely used in drainage, fire protection, municipal and other fields . However, selecting the appropriate type of butterfly valve based on the working conditions is a challenge, especially when it comes to double eccentric and triple eccentric valves. Although these two types of valves differ by only one character, their performance and applicable scenarios are quite different. This article delves into the structural principles to dissect the core differences between them and provide professional guidance for engineering selection.

The “eccentric structure” reduces friction during the opening and closing process and extends the service life of the seal by offsetting the rotation axis of the butterfly plate from the center of the valve body. Double eccentric and triple eccentric valves differ in the amount and direction of the eccentricity.

1. Double Eccentric Butterfly Valve

1. The valve stem is offset from the center of the butterfly plate.

2. The valve stem is offset from the center of the valve body’s sealing surface.

The two eccentricities work together to ensure that the butterfly plate completely disengages from the sealing surface during opening and closing, achieving “zero friction”.

When fully closed, the butterfly plate forms a “surface contact compression seal” with the sealing surface under the torque (unlike the single eccentric valve’s line contact), resulting in higher sealing pressure and a sealing performance of the soft seal material that can approach “zero leakage”.

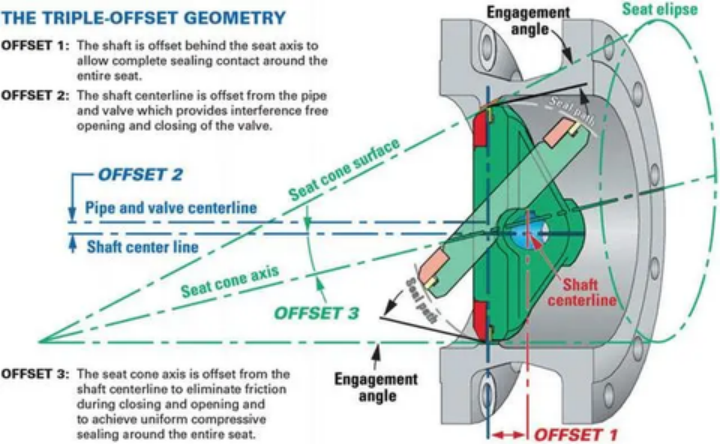

2. Triple Eccentric Butterfly Valve

1: The valve stem is offset from the center of the butterfly plate.

2: The valve stem is offset from the center of the valve body.

3: The sealing surface is offset from the plane of the butterfly plate (the sealing surface is inclined).

During opening and closing, the inclined sealing surface forms a “wedge fit” with the sealing surface of the valve body, creating a metal-to-metal hard seal. The higher the medium pressure, the tighter the sealing surface is compressed, and the more reliable the sealing performance, achieving “hard seal zero leakage”.

VI. How to Select the Type:

Pressure and Temperature:

pressure (≤PN10) and normal temperature: Centerline butterfly valve / Double eccentric butterfly valve;

Pressure (PN10-PN16) and temperature (≤200℃): Double eccentric butterfly valve;

Pressure (≥PN25) and temperature (≥200℃): Triple eccentric butterfly valve Sealing :

Zero leakage required: Double eccentric butterfly valve; / Triple eccentric butterfly valve ;

Strong corrosion / high temperature requires hard seal: Triple eccentric butterfly valve .

From the centerline type to the triple eccentric type, the upgrade of butterfly valves in eccentric structure is essentially a technological evolution from “solving friction” to “breaking through the limits of working conditionsWhen selecting, choose the appropriate structure based on your own working conditions to achieve the best balance between cost and service life while ensuring performance.