Hydraulic control valves are the general term for a series of water pressure control valves. According to different working conditions and functions, they are classified as remote control float valves, pressure reducing valves, slow-closing check valves, flow control valves, pressure relief valves, hydraulic electric control valves, and pump control valves, etc.

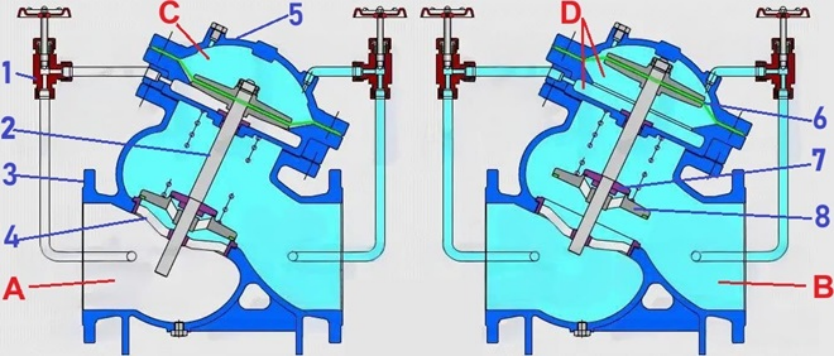

According to the main valve structure, it can be divided into two types: T-type straight-through and Y-type direct-flow. The direct-flow valve body has a smaller flow resistance and a larger flow capacity. However, it has a larger external dimension and a higher cost.

According to the control element, it can be divided into diaphragm type and piston type. The diaphragm type has a high control sensitivity and will not get stuck, but it can only be used in low-pressure pipelines with PN16 and PN25. The piston type has a high pressure resistance, a long service life, and is convenient for replacing the sealing ring. However, it may get stuck when there is a lot of impurities. For a nominal pressure of PN40, the piston type structure should be adopted. For large diameters, the piston type structure should also be adopted.

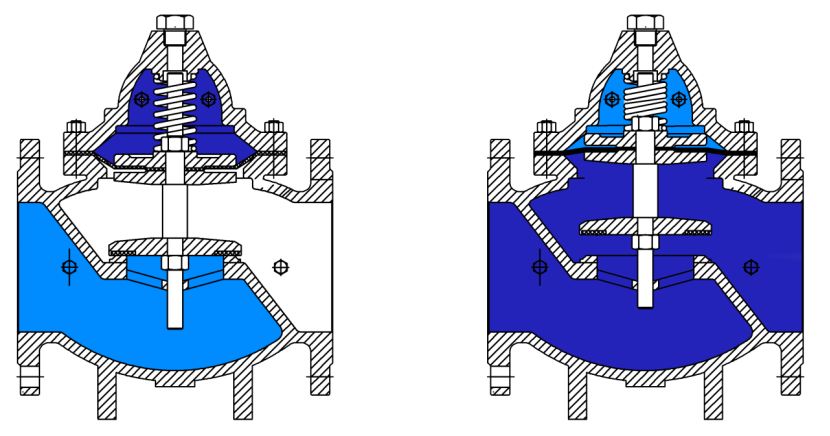

According to the number of control chambers, it can be divided into single-chamber type and double-chamber type. The single-chamber type has a simple structure and the valve body is less likely to have external leakage. The double-chamber type has the diaphragm lower chamber separated from the medium, not affected by medium pressure disturbance, and provides more precise control. However, when the valve stem seal wears, there is a risk of external leakage from the lower chamber.