Gate Valve Supply & manufacture

What is gate valve?

This valve is mainly used to control the flow of fluid in the pipeline to achieve fluid cutoff and regulation. Its working principle is based on a tight seal between the gate and the seat. Gate valve structure is simple and reliable, widely used in petroleum, chemical, water treatment, energy and other fields. When used, the gate valve can only be in a fully open or fully closed state, and can not be used for regulation and throttling

Advantages of gate valves

Simple structure and easy maintenance. Gate valves maintenance is relatively simple and easy to repair and replace. Good sealing and stable flow control. It has good sealing performance and can effectively control the flow of fluid. Gate valves have strong applicability in various working conditions, not only can be used for conventional fluid control, but also can be used for high temperature, high pressure, corrosive media and other special working conditions. The sealing surface of gate valve is usually made of hard alloy and other wear-resistant materials, which can effectively extend the service life and reduce the number of maintenance.

According to the sealing :Soft sealing

Soft seal rising stem gate valve

Rising resilient seated gate valves solve the problem in general gate valves such as leakage, rusting etc. and saves installation space.

Soft non-rising stem gate valve

Soft seal smell valve is the replacement of traditional smell valve, the use of elastic disc to produce micro deformation compensation effect to achieve good sealing effect, the valve has a light switch, reliable seal elastic memory and long service life and other significant advantages.

According to the sealing :Hard sealing

Rigidity seal rising stem gate valve

The rigidity seal rising stem gate valve makes the switching torque of the valve smaller, the operation is light and flexible, and the labor intensity of the operator is reduced. It can effectively cut off or connect the medium in the pipeline, and realize the precise control of the fluid medium.

Rigidity seal non-rising stem gate valve

Rigidity seal non-rising stem gate valve is a high performance, high reliability fluid control equipment, suitable for a variety of industrial pipe systems, especially in the need for high sealing performance, high temperature resistance, corrosion resistance.

According to the

Grooved gate valve

The groove gate valve uses hard materials as the sealing surface..Its unique flat bottom design can effectively prevent debris accumulation at the bottom of the valve, making the fluid smooth, overcoming the problem

Knife gate valve

The knife gate valve, also known as the blade valve, is a type of valve that features a simple structure, small size, light weight, excellent sealing performance, corrosion resistance, and flexible operation.

signal gate valve

The signal gate valve is a powerful and versatile valve type, especially suitable for controlling a variety of fluid media and requiring high sealing and operating force.

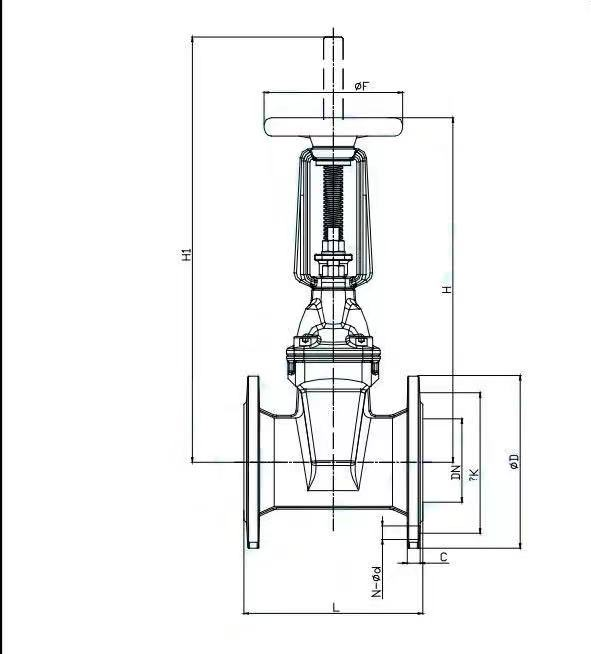

Specifications:

- Size range: DN50- DN1000

- Working pressure: PN10 - PN16

- Working temperature: -20°C-100°C

- Drive mode: manual, electric, pneumatic optional

- Connection: flange, clamp, welding and other connection methods are optional

Fields of application

Water and Waste water Treatment

Gate valves are commonly used in water supply and waste water treatment systems to control the flow of fluids, isolate sections of the pipeline for maintenance, and regulate water levels.

Oil and Gas Industry

In the oil and gas sector, gate valves are employed to control the flow of hydrocarbons, prevent back flow, and isolate sections of the pipeline during maintenance or emergency situations.

Chemical Processing

Chemical plants rely on gate valves to isolate equipment, control fluid flow, and prevent the mixing of incompatible chemicals.

General Industrial Applications

Gate valves find widespread use in various industrial processes, including food processing, pharmaceutical manufacturing, and paper production, among others.

Pipeline Systems: Gate valves are integral to pipeline systems, enabling operators to control flow, isolate leaks or damage, and facilitate maintenance activities.

Frequently asked Questions and Answers

The reasons for the failure of gate valve stem lifting may include thread damage caused by excessive operation, lack of lubricant or lubricant failure, valve stem bending and twisting, insufficient surface finish, inaccurate mating tolerances, valve stem nut tilt, improper material selection, corrosion of thread wave media, and lack of protection of open valves resulting in valve stem threads sticking with dust or rust.

For the problem of gate valve stem lifting failure, the following measures can be taken: check and tighten the bolts to ensure adequate connection; Inspect and repair defects in seal flanges and grooves; Replace damaged seals; Check and adjust the match of valve stem and valve stem nut; Clean stem threads and apply suitable lubricant; Replace damaged stem or stem nut, etc.