Check Valve Supply & Manufacture

What is a check valve?

A check valve, also called a one-way valve, is a device that allows the flow of fluids to move only in one direction. The main function of a check valve is to prevent medium backflow in the system. Check valves are cheap, effective, and easy solutions to a potential issue.

Advantages of Check Valves:

- Able to endure high and low pressure conditions.

- Able to be used horizontally and vertically.

- Self-actuated and fast acting.

- Lower maintenance costs.

- Do not require power to operate.

According to connection method-Check Valve

Wafer Check Valve

Wafer check valve is a kind of automatic valve used for preventing back flow of medium, featuring compact structure, easy installation and good sealing performance. The valve is equipped with spring and disc, and the disc realizes quick closing by spring elasticity to prevent the medium from flowing backward. Suitable for water, steam, oil and other media in the pipeline system.

Grooved Rubber Flap Check Valve

Grooved rubber flap check valve is suitable for water, steam, oil and other media in the pipeline system, to prevent back flow of media. The valve flap is made of rubber, which has good elasticity and sealing performance. The groove connection makes the installation and dismantling of the valve easy and quick

Grooved Silent Check Valve

Grooved silent check valve is suitable for fire fighting pipeline of water supply and drainage pipeline. The product has the various advantages of flanged silent check valve, but also has the characteristics of small volume, light weight, easy installation, low project cost. The valve is suitable for a wide range of media, including water, steam, oil and so on. It is especially suitable for occasions that require quick installation and disassembly.

According to structure-Check Valve

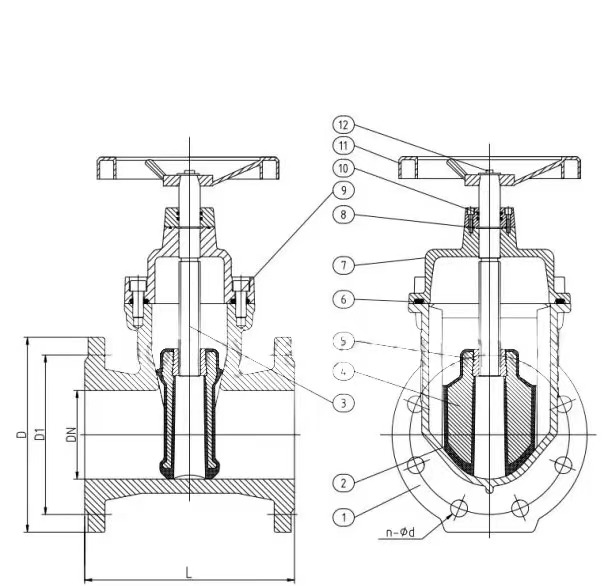

Swing Check Valve

Swing check valve is mainly used to prevent the medium from flowing backward in the pipeline. The valve has a compact structure, good sealing performance, suitable for a variety of media and working environment.

Ball check valve

Ball check valve is one of the best check valves used in sewage and drainage systems. In the process of use, the ball will roll with the water flow and constantly roll over the sealing surface, that is, it has a cleaning effect on the sealing surface.

Slow Closing Check Valve

Slow closing check valve is widely used in high-rise buildings, living areas and other water supply network systems and urban water supply projects. It can not only prevent media backflow, but also its slow opening and closing design makes the valve

Specifications:

- Size range:DN40- DN1200

- Working pressure:PN10 - PN16

- Working temperature:-20°C-100°C

- Connection: flange, wafer, groove

- Structure: swing,rubber flap, butterfly, ball

Production Process

Fields of application

Check valve is a kind of valve used to control the one-way flow of fluid, which is widely used in various industrial, civil, agricultural and public facilities and other fields. The following are some of the main application areas of check valves:

Water supply and drainage systems

In water supply plants, check valves are installed at the outlet of pumps to prevent water from backing up back into the pumps and causing damage to the pumps. In sewage treatment plants, check valves are also widely used in various pipelines to prevent backflow of sewage.

Oil and gas industry

During the extraction, transportation and processing of oil and gas, liquid or gas in pipelines may back up for various reasons. To prevent this from happening, check valves need to be installed in pipelines.

Power industry

In boilers and other thermal systems, check valves can ensure the safe operation of the system and prevent the backflow of media.

Chemical Processing

Chemical plants rely on gate valves to isolate equipment, control fluid flow, and prevent the mixing of incompatible chemicals.

Frequently asked Questions and Answers

Reason: It may be caused by damaged valve flap, spring failure, impurities stuck, etc..

Solution: check whether the valve flap and spring is damaged, clean the impurities, replace the damaged parts.

Reason: It may be caused by rusty valve stem, stuck, poor lubrication and other reasons.

Solution: check whether the valve stem is rusty or stuck, clean and lubricate, replace the damaged parts.

Reason: it may be caused by improper installation position, untight connection, wrong direction and other reasons.

Solution: Check whether the installation position and direction are correct, make sure the connection is tight, and follow the correct installation steps.