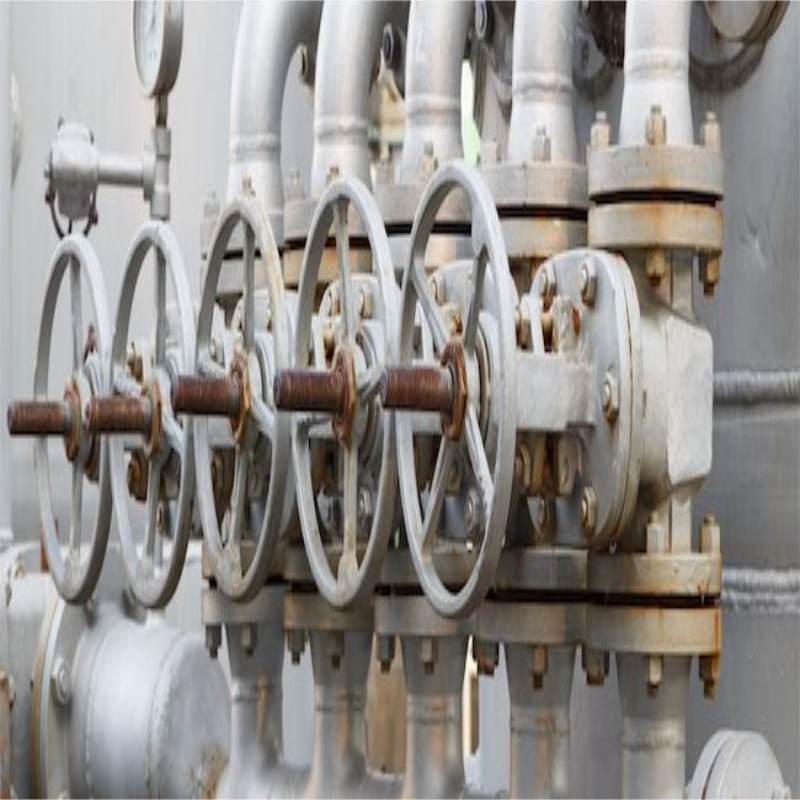

Cast steel gate valves are linear motion valves that control the flow of liquids, gases, or slurries by raising or lowering a gate (or wedge) element perpendicular to the flow direction. The gate, usually made from stainless steel or a special alloy to match the media it handles, completely blocks or permits the passage of fluids when fully closed or open, respectively. The body and other critical components of these valves are cast from steel, a material renowned for its strength, corrosion resistance, and ability to withstand high pressures and temperatures.

Cast steel gate valve: It is one of the commonly used cut-off valves. It is mainly used to connect or cut off the medium in the pipeline, and is not suitable for regulating the flow of the medium. Cast steel gate valves are suitable for a wide range of pressures, temperatures and diameters, and are especially suitable for medium and large diameter pipelines. Nominal size DN15~DN800, nominal pressure 1.6MPa~20.0MPa, sealing surface made of asbestos graphite or flexible graphite, working temperature ≤570℃, operation modes include manual, gear transmission, electric, pneumatic, etc., suitable for water, steam, oil products in the medium pipeline.

The gate, the primary flow-controlling element, is precision-machined to ensure a tight seal when in the closed position. It can be either a solid wedge or a split wedge design, with the latter offering better sealing performance in high-temperature applications due to its ability to expand evenly. The stem, connecting the gate to the actuator (either manual, electric, or pneumatic), must be strong enough to withstand the force required to move the gate and resistant to corrosion. It is often coated or plated for additional protection.

Compact structure, reasonable design, good valve rigidity, smooth passage and small flow resistance coefficient.The sealing surface is made of stainless steel or carbide and has a long service life.Using asbestos graphite or flexible graphite, the sealing is reliable and the operation is light and flexible.Various piping flange standards and flange sealing surface forms can be adopted to meet various engineering needs and user requirements. Widely used in pipelines of various systems in petroleum, chemical industry, hydraulic and thermal power stations.

Cast steel’s inherent strength and resistance to deformation make it an ideal material for gate valves handling high-pressure and high-temperature fluids. The valves can withstand harsh operating conditions, ensuring reliable service over extended periods.

Precision machining and advanced sealing technologies ensure that cast steel gate valves provide excellent shut-off capabilities, minimizing leaks and ensuring compliance with stringent industry standards.

Available in a wide range of sizes, pressures, and temperature ratings, cast steel gate valves can be customized to suit diverse application requirements. They are suitable for handling various fluids, including water, oil, gas, chemicals, and slurries.

Many cast steel gate valves feature designs that facilitate easy access to internal components for maintenance and repair. This minimizes downtime and reduces operational costs.With proper care and maintenance, cast steel gate valves can last for decades, offering a cost-effective solution for long-term fluid control needs.

Cast steel gate valves find applications across numerous industries, where their robust construction and reliable performance are invaluable assets. Some of the most common applications include:Regulating flow in water supply networks, sewage treatment plants, and irrigation systems.

Petrochemical and Refining: Controlling the flow of hydrocarbons, chemicals, and other process fluids in refineries and petrochemical plants.