1. Introduction

The globe valve plays a very important role in the pipeline, which is used to cut off the fluid, regulate the flow rate, and ensure safety in the event of safety accidents. It is very important to choose the correct and excellent quality of the globe valve for safe production。

2. Basic functions and application scenarios of globe valves

As a key fluid control valve, the globe valve’s basic function is to cut off or connect the fluid through the lifting movement of the valve disc. In the energy and heavy industry, power plant and nuclear power plants of high temperature and high pressure steam pipeline, oil refinery crude oil pipeline are can be used。

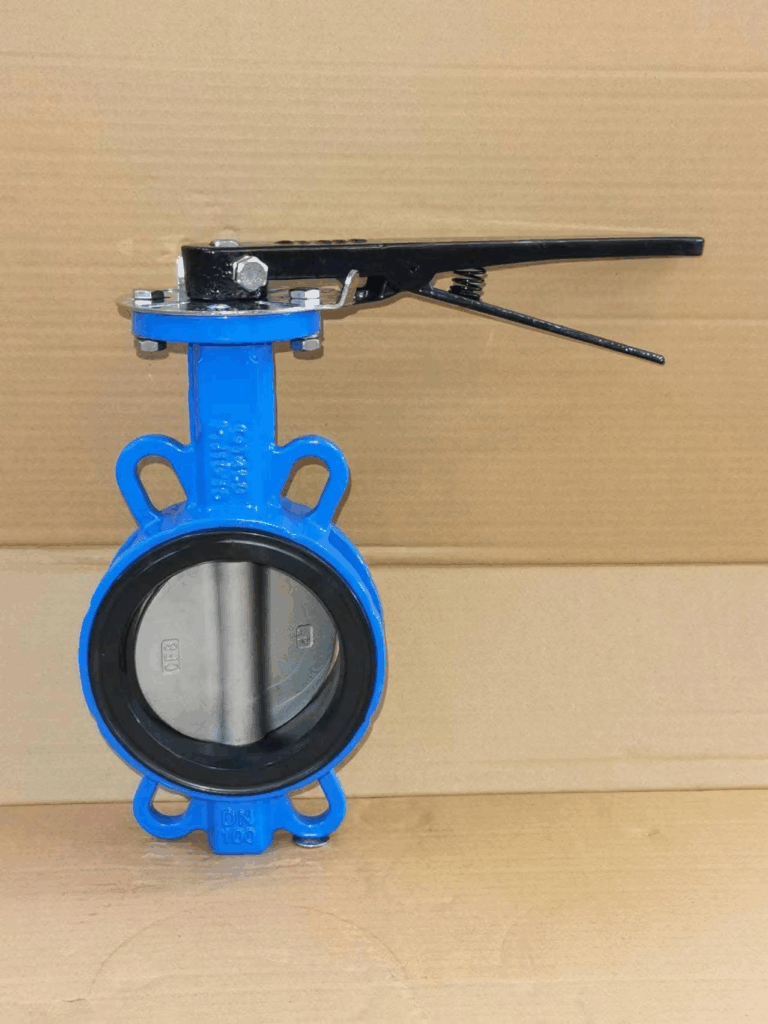

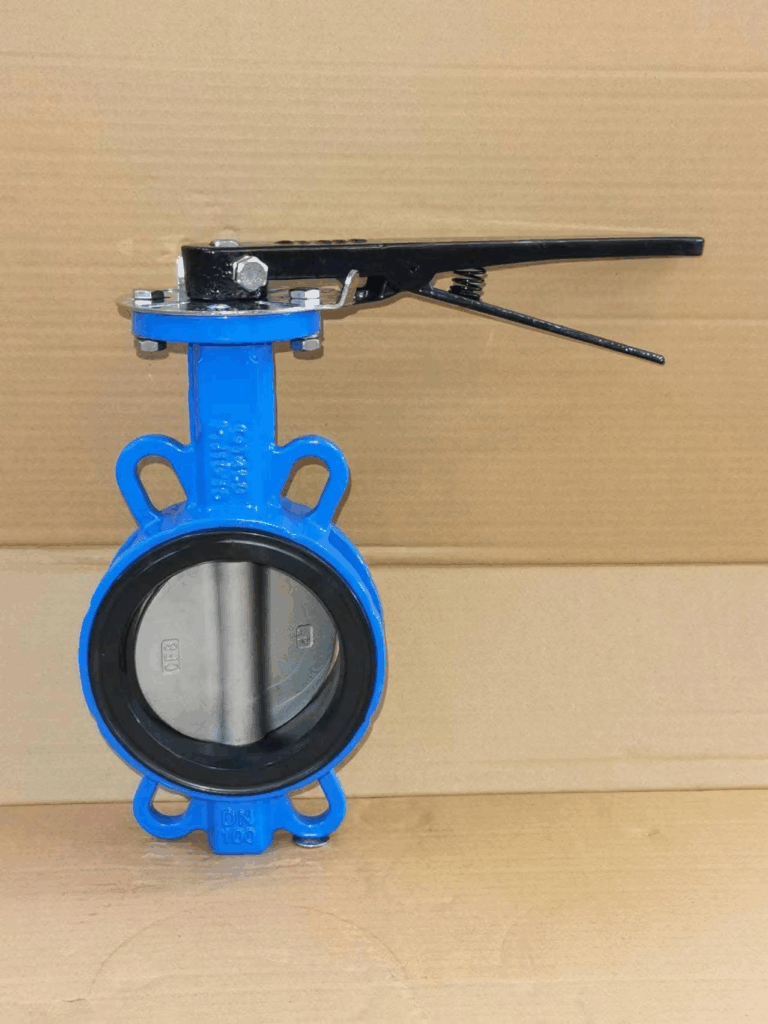

- Butterfly Valves

Structure and working principle:

Screw the handle to drive the stem, so that the Angle of the control valve plate changes from 0 to 90°, which can change the flow rate。.

Advantages:

Butterfly valve is composed of valve body, butterfly plate and other components, simple and compact structure, fast opening and closing and material saving, especially suitable for large diameter pipelines。

Limitations:

Butterfly valve is not suitable for high pressure, high particle, high viscosity media and precision adjustment, two-way sealing scenarios。.

Applicable scenarios:

Water treatment, air conditioning system and fire network。

- Gate Valves

Gate valve is composed of valve body, gate plate, etc., through the vertical take-off and fall of the gate plate to achieve the opening and closing of the valve, but it is not recommended to adjust the flow rate. Divided into hard seal and soft seal.。

Advantages:

When the gate valve is fully opened, it is all through straight through, without flow resistance, and zero pressure drop is realized。(such as knife-type gate valves).

Limitations:

The gate valve can not adjust the flow rate for a long time, because the medium washes the gate plate when it is half open, it is easy to damage the sealing surface, resulting in leakage and wear.

Applicable scenarios:

Gate valves are suitable for large diameter pipeline fully open or fully closed scenarios, such as chemical, petroleum, power and water supply systems.

- Plug Valves

Structure and working principle:

The plug valve is composed of a valve body, a cock (plug), a valve stem, etc., and rotates the plug body 90 degrees to align or misposition the channel to achieve opening and closing

Advantages:

The plug design of the plug valve has a self-cleaning function, and the sealing surface is wiped with each other when rotating to prevent the accumulation of particles or crystalline media in the valve, and the structure is compact and the sealing is reliable。

Limitations:

The disadvantages of the plug valve include easy wear of the sealing surface, high risk of seal failure under high pressure and high temperature, large operating torque and inflexibility, not suitable for granular media and large diameter pipelines, and limited accuracy when regulating flow。

Applicable scenarios:

Situations that require fast switching and low maintenance。.

6. Key factors for globe valve selection

The acid and base degree of the fluid, the temperature and pressure of the fluid at work, and the caliber of the pipe.

Operating conditions: fully open/close or regulate flow.

Space constraints: consider the installation space and operating space of the valve.

Maintenance requirements: select valves that are easy to clean and maintain.

7. Summary and selection suggestions

Summary:

All the valves in the world have their own advantages and disadvantages, according to the actual working conditions to choose the most suitable valve, in order to ensure operation safety and improve production efficiency。

Selection suggestions:

Butterfly valve: suitable for clean fluids and occasions that require fast switching.

Gate valve: suitable for fluids containing solids and particles and occasions that require completely unobstructed flow.

Plunger valve: suitable for fluids containing solids, particles or sludge and occasions that require fast switching.