API 608 vs. API 6D: Key Differences, Applications, and Specifications

Introduction

API norms (American Petroleum Institute) is one of the most generally exercised ball valve norms in the United States. API norms carry API 6D(Pipeline Valves/ Pipeline valves- Ball valves Globe Valves) and AP1 608( Metal Ball valves- Angle and Bearing End Ball Valves/ Globe valves). These norms define conditions for ball valve project, accoutrements, welding, testing, confines and interpretation.

API 6D valves are a vital channel valve project and manufacturing metric in the oil painting and gas assiduity. It covers a variety of valve manners, involving gate valves, ball valves, check valves, block valves, etc. These valves play a crucial part in the product, transportation and processing of oil painting and gas.

API 608 is a standard-issue developed by the American Petroleum Institute for essence ball valves with flanges, vestments and welded connections. It’s able for ball valves in sizes from 1/4 point to 12 elevation and rated for ANSI working out pressures up to 2500 psi. The standard-issue specifies conditions for valve body, seat, seal and ball accoutrements, harborage figure, test styles, pressure/ temperature conditions and markings.

The following composition will give a detailed preface to the differences, operations and specifications of API 608 and API 6D norms.

What’s an API 6D valve?

API 6D description valve standard: issue workable to channel transportation systems.

Applicable valve manners: ball valves, gate valves, check valves, etc.

Main features:

Bidirectional sealing project to help leakage.

Applicable to long- distance channels, furnishing high security and sealing interpretation.

Need to meet conflagration forestallment, leakage forestallment and high pressure defiance conditions.

Common operations: oil painting, gas, chemical and water treatment diligence.

3. What’s an API 608 Ball valve?

Description of API 608: project metric for floating ball valves.

Main features:

Able for artificial operations, not long- distance channels.

Aimed substantially for medium pressure surroundings.

One- expressway sealing structure, simple conservation.

Operations: chemical, food processing, medicinal diligence, etc.

4. What’s the disparity Between API 608 and API 6D Ball valve?

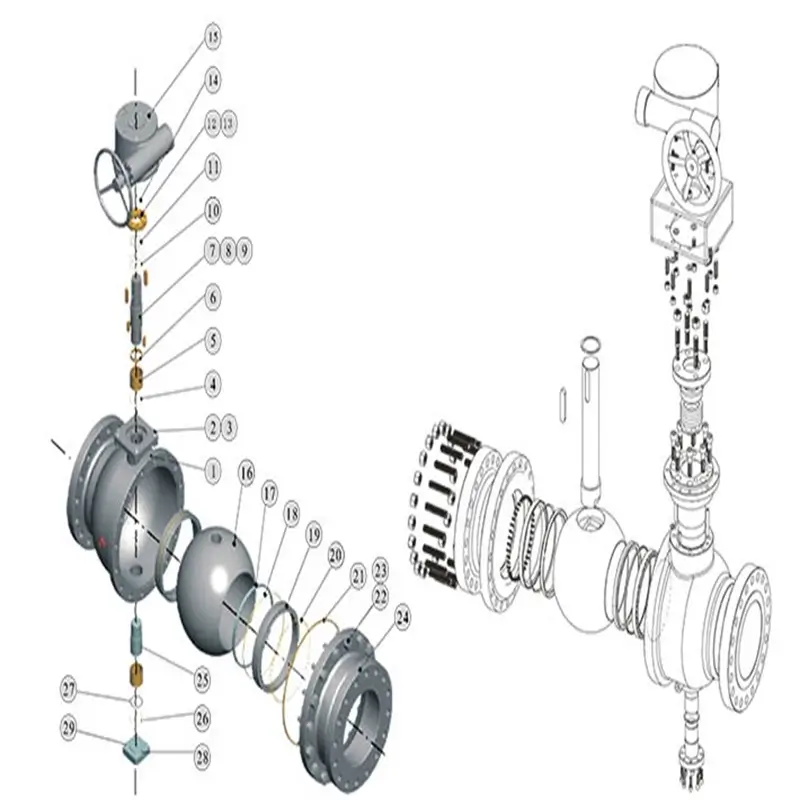

Nonidentical structures: API 608 is substantially a floating ball valve, while API 6D is substantially a fixed ball valve.

Operation scripts: MAPI 6D is able for long-distance channels, while API 608 is able for general artificial purposes.

Sealing system: API 6D uses bidirectional sealing, while API 608 uses unidirectional sealing.

Pressure and security norms: API 6D needs to meet more strict leakage and security norms, while API 608 is able for medium pressure surroundings.

5. Structure And Operation

API 6D structural features fixed ball, more able for high pressure terrain.

Able for long- distance channels, generally need to meet the double-barreled insulation and discharge(DBB) conditions.

API 608 structural features floating ball project, good sealing interpretation.

Further able for short- distance fluid control systems.

Operation field comparison:

API 6D is substantially exercised for oil painting and gas channels and long- distance systems.

API 608 is substantially exercised in chemical, food, medicinal and general diligence.

6. Installation And Conservation

API 6D valve installation: Due to its daedal project, professional installers are needed.

The conservation circle is long and generally adopts online conservation project.

valve installation: The structure is fairly simple and ready to install and replace.

The conservation cost is low, but the seals may need to be displaced regularly.

7. Usage And Specifications

API 6D specification demands Applicable to high- pressure, voluminous- periphery channels.

Conflagration-evidence and leak-evidence project, in line with transnational channel norms.

API 608 specification conditions Applicable to medium and low pressure conditions, generally ANSI 150~600 grades.

Substantially concentrated on artificial fluid control preferably than long- distance transportation.

8. Conclusion

API 608 ball valves are exercised in process channels, with constant switching missions and short indulgence life. In extension, the periphery isn’t voluminous, so it’s ready to replace. API 6D ball valves are exercised in long- distance oil painting and gas channels. They’ve a voluminous periphery, high pressure, ignitable and intensive medium, and long- distance channels usually flow through areas with daedal geographical surroundings, harsh climates, and voluminous ambient temperature changes. The channel investment is huge, and after being set into operation, it’s needed to operate continuously for a long time. When the channel is operating typically, the ball valve is open, but once a fault occurs and needs to be closed, the valve must be closed snappily and reliably. In extension, API 6D ball valves are delicate to replace due to procurators similar as voluminous periphery, interred installation, and welding connection with channels, and formerly recreated, the cost is high. thus, API 6D ball valves for long- distance channels bear advanced security, trustability, sealing and energy than API 608 ball valves to insure long- tenure safe and dependable operation of long- distance channels.

API 6D is especially able for long- distance channels. It has multitudinous places similar as sewage discharge, venting, and overpressure relief. It substantially adopts a fixed ball structure to meet the requirements of high pressure and voluminous periphery. API 608 is substantially exercised for fragile- periphery and low- pressure occasions, and its ball valve is usually a floating ball structure. API 6D is nonidentical from API 608 in tours of pressure position, periphery range, structural project and examination conditions.

In short, when opting a ball valve, the applicable ball valve type should be named tallying to the special operation.