The difference between center-line butterfly valves, double-offset butterfly valves, and triple-offset butterfly valves.

Characteristics of midline butterfly valve: The stem axis, disc center, and valve body center are on the same line. The structure is relatively simple, and the valve seat is usually made of rubber or EPDM. The valve plate and the valve seat are squeezed to achieve sealing performance. Therefore, frequent squeezing and friction will intensify the wear of the valve seat, making it easy to damage.

Double eccentric butterfly valve: The valve shaft deviates from the centerline of the valve body, and the valve plate deviates from the centerline of the valve body. The axis of the valve stem and the center of the valve plate do not coincide with the center of the valve body. This design enables the valve plate to quickly separate from the valve seat during the opening process, reducing unnecessary compression and friction between the valve plate and the valve seat, thereby extending the service life of the valve.Double eccentric butterfly valves can use metal valve seats to enhance their high temperature resistance.

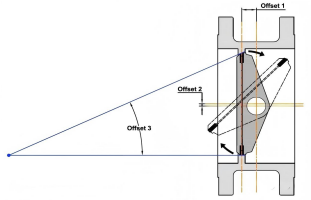

Triple eccentric butterfly valve, the valve shaft deviates from the centerline of the valve body, the valve plate deviates from the centerline of the valve body, and the sealing surface of the valve plate is inclined at a certain angle with the valve plate, forming a conical surface. Make the opening and closing process almost frictionless, reduce torque, and make opening and closing more lightweight.

Mid line butterfly valves are generally suitable for low pressure, PN10, 16. Medium low temperature

Double eccentric butterfly valves are generally suitable for medium and low pressure PN16,25, medium temperature (less than 200 degrees Celsius)

The three eccentric butterfly valve can withstand high temperature, high pressure, and corrosive media. The structure is complex and the maintenance cost is high, long service life.