Part I: General Introduction

The remote control float valve consists of a main valve and its attached conduit, pilot valve, needle valve, ball valve and pressure gauge. When the pipeline supplies water from the water inlet, since the needle valve, ball valve and float valve are normally open, water enters the pool through the micro filter, needle valve, control room, ball valve and float valve. At this time, no pressure is formed in the control room, the main valve is opened, and the water tower (pool) supplies water. When the water level of the water tower (pool) rises to the set height, the float floats up to close the float valve, the water pressure in the control room increases, pushing the main valve to close, and the water supply stops. When the water level drops, the float valve reopens, the water pressure in the control room drops, and the main valve opens again to continue supplying water to maintain the set height of the liquid level.

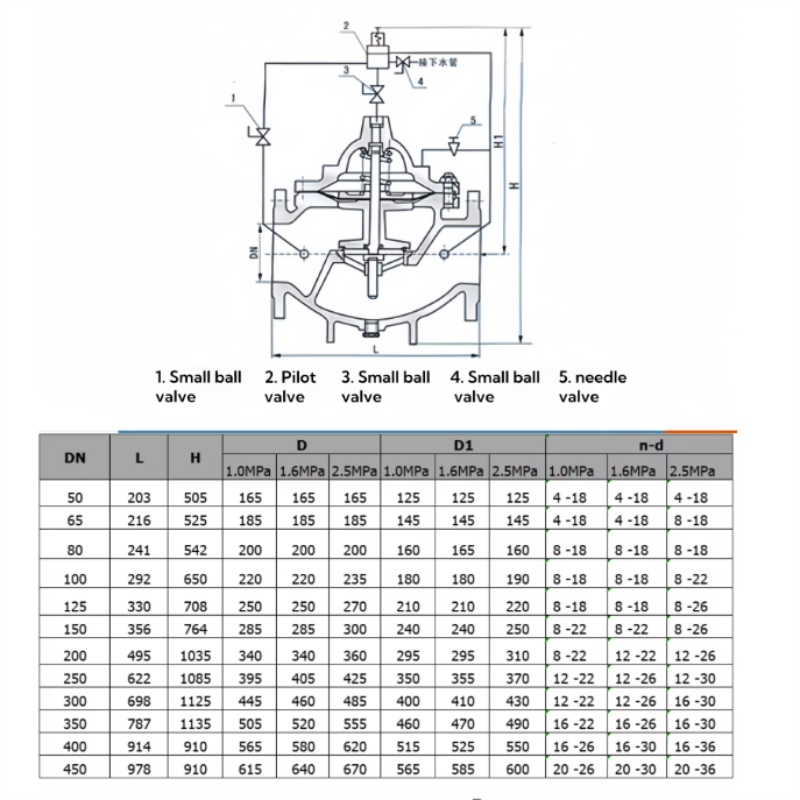

Part II: Technical Parameters

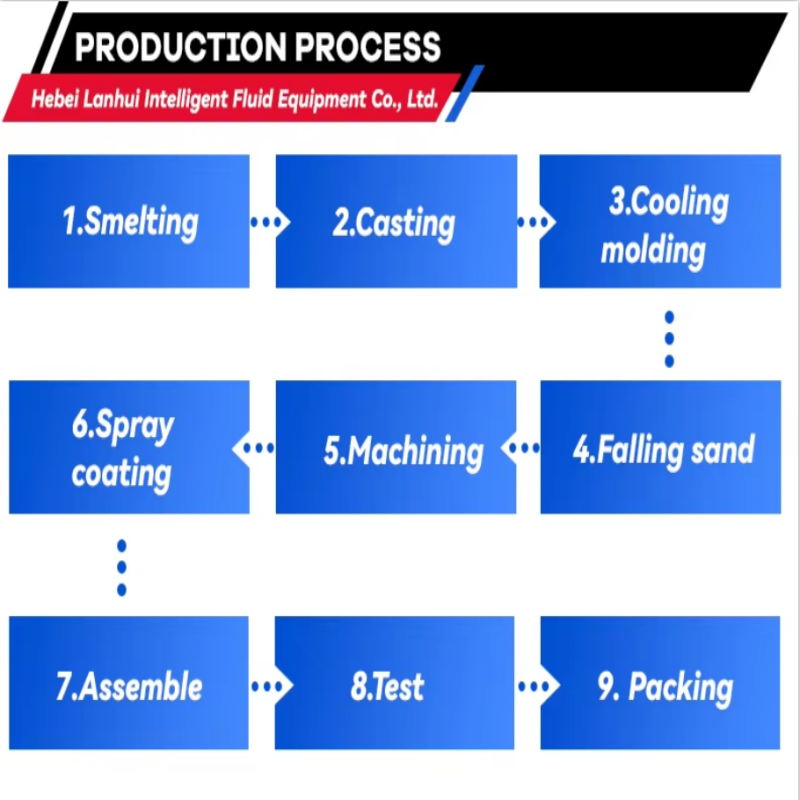

Part III: Production Process

Part IV: Parts Materials

1. Ductile iron valve body.

Ductile iron has the advantages of high strength, good toughness, wear resistance, vibration damping and so on. Production costs are relatively low, which is conducive to reducing the manufacturing cost of the valve. Good processing performance, easy to manufacture complex valve structure.

- Copper tube

①Pressure regulation: One of the main functions of the copper tube of the pressure reducing valve is to regulate the fluid pressure. When the fluid passes through the pressure reducing valve, the copper tube reduces the fluid pressure to the set value through the internal structure design to meet the needs of downstream equipment.

②Flow control: The copper tube of the pressure reducing valve can also control the fluid flow. Under high pressure, the copper tube can ensure that the fluid flows smoothly and continuously to the target equipment to avoid unstable flow caused by pressure fluctuations.

③Safety protection: The copper tube of the pressure reducing valve has excellent high temperature resistance and corrosion resistance. It can withstand various harsh environments and provide safety protection for the system. The copper tube can also prevent overload and overpressure, protecting downstream equipment from damage.

Part V: Valve Applications

- High-rise buildings and residential areas: In the water supply systems of high-rise buildings and residential areas, 100X remote control float valves are used to automatically control and adjust the liquid level of pools or water towers to ensure stable water pressure and water volume to meet daily water supply needs.

- Industrial facilities: In the water supply systems of various industrial and mining enterprises, 100X remote control float valves can improve production efficiency and ensure stable water supply during the production process through precise liquid level control.

3. Water conservancy facilities: In water conservancy facilities such as reservoirs, canals, and rivers, 100X remote control float valves are used to automatically control water levels to avoid disasters such as floods or droughts and ensure that water levels fluctuate within a normal range.

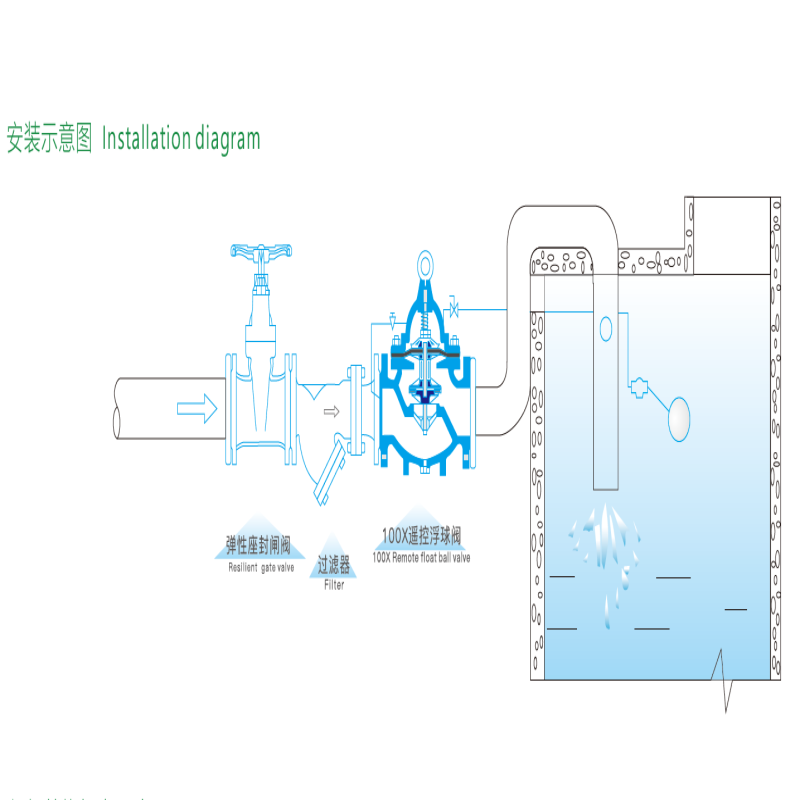

Part VI:Installation Diagram