Part I: General Introduction

LANHUI Ductile Iron Handle Wafer Butterfly Valve has compact structure, easy 90°switching, reliable sealing and long service life, and is widely used in water supply and drainage of water plants, power plants, steel mills, papermaking, chemical industry, catering and other systems as regulating and shut-off use. The valve has a two-way sealing function, the installation is not controlled by the medium flow direction, also not affected by the space position, can be installed in any direction.

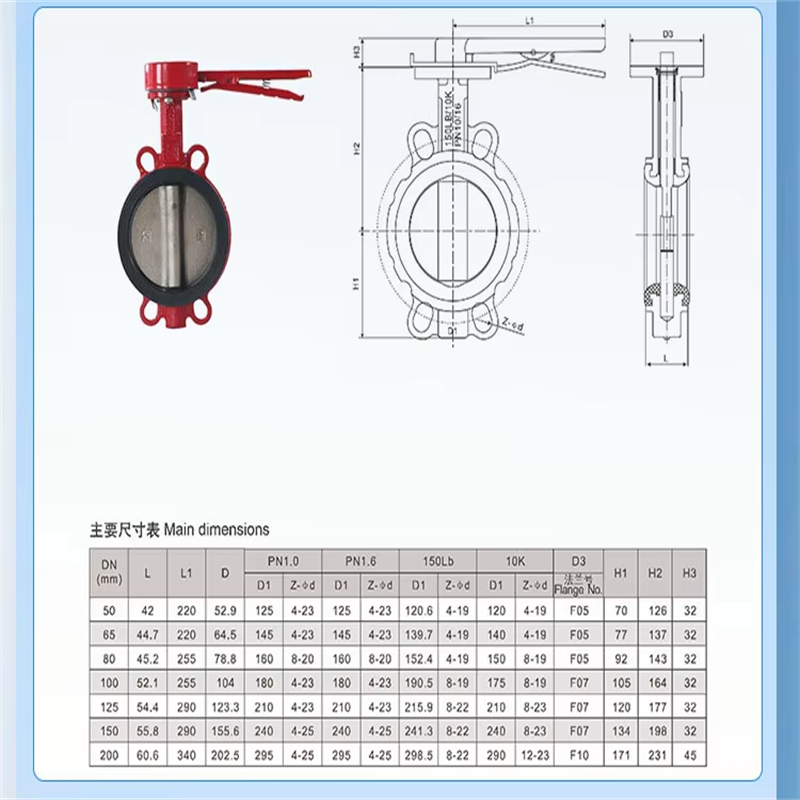

Part II: Technical Parameters

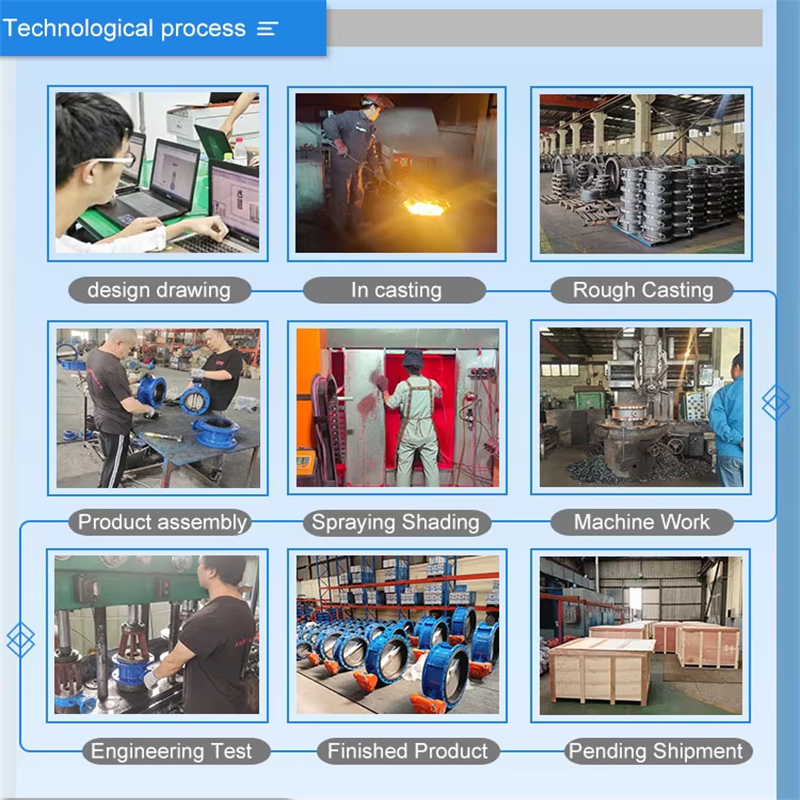

Part III: Production Process

Casting – sand cleaning – machining – spraying – assembling -Test pressure -Storage, the checks at all levels achieve precision work and good quality.

Part IV: Parts Materials

1. Ductile iron valve body.

Ductile iron has the advantages of high strength, good toughness, wear resistance, vibration damping and so on. Production costs are relatively low, which is conducive to reducing the manufacturing cost of the valve. Good processing performance, easy to manufacture complex valve structure.

- 2.Seat with different material

Rubber sealing ring can be vulcanised on the valve body or mounted on the butterfly plate, which can be applied to different characteristics of the medium for users to choose.

NBR: Nitrile rubber is a copolymer made by polymerisation of acrylonitrile and butadiene monomers, mainly produced by low temperature emulsion polymerisation method, with excellent oil resistance, high abrasion resistance, good heat resistance and strong adhesive force

EPDM: EPDM is basically a saturated polymer, very good aging resistance, good weather resistance, excellent electrical insulation properties, good chemical resistance, good impact elasticity.

PTFE: Polytetrafluoroethylene is commonly known as the king of plastics, is the world’s best engineering plastics, PTFE has excellent chemical stability, corrosion resistance, sealing, self-lubricating non-stick, electrical insulation and good anti-aging ability.

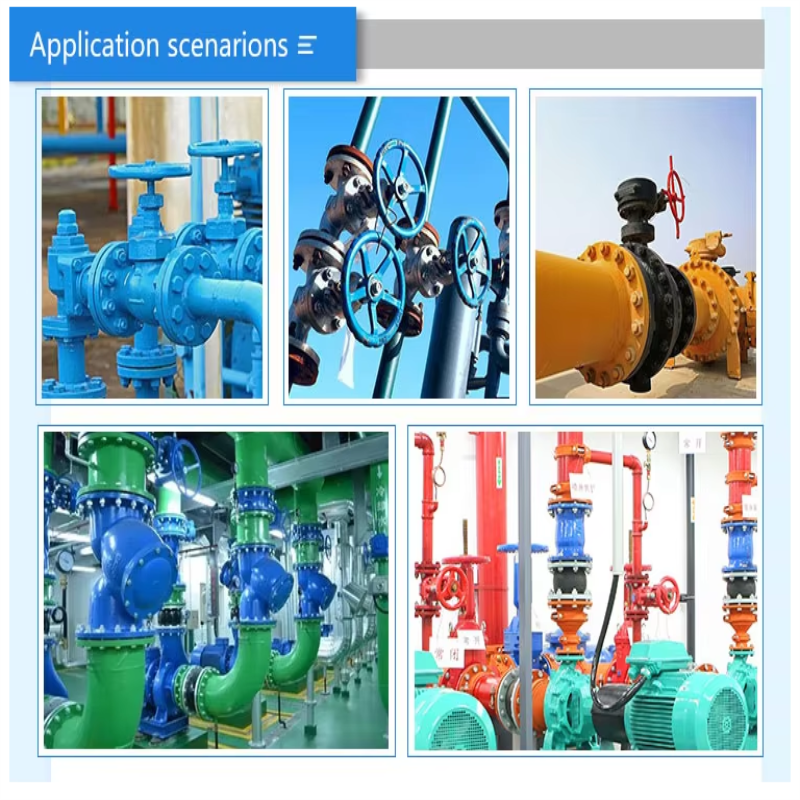

Part V: Valve Applications

I. Water supply and drainage engineering

For example, it is used to control the water flow in the water supply pipeline of waterworks. Compared with other valves, the centerline soft seal butterfly valve has less fluid resistance. In large water supply and drainage pipelines, this feature helps to reduce energy loss and improve water supply efficiency.

II, HVAC system

In centralized heating or central air-conditioning systems, centerline soft seal butterfly valves are used to regulate the flow of hot water or refrigerant. Take the central air-conditioning system of a hotel as an example, in the branch piping connection between the air-conditioning mainframe and each floor, a centerline soft-seal butterfly valve is installed. By adjusting the opening of the butterfly valve, the refrigerant flow to each floor can be accurately controlled to regulate the indoor temperature in different areas.

III, the chemical industry

In the chemical production process, many pipelines need to transport various corrosive liquids or gases. Centerline soft seal butterfly valve can be used to control the flow of these chemical media. For example, in the chemical industry, sulfuric acid conveying pipeline, it can withstand the corrosive nature of sulfuric acid, and can accurately adjust the flow of sulfuric acid in accordance with production requirements.

Part VI:Our Advantages