Paragraph 1: Overview

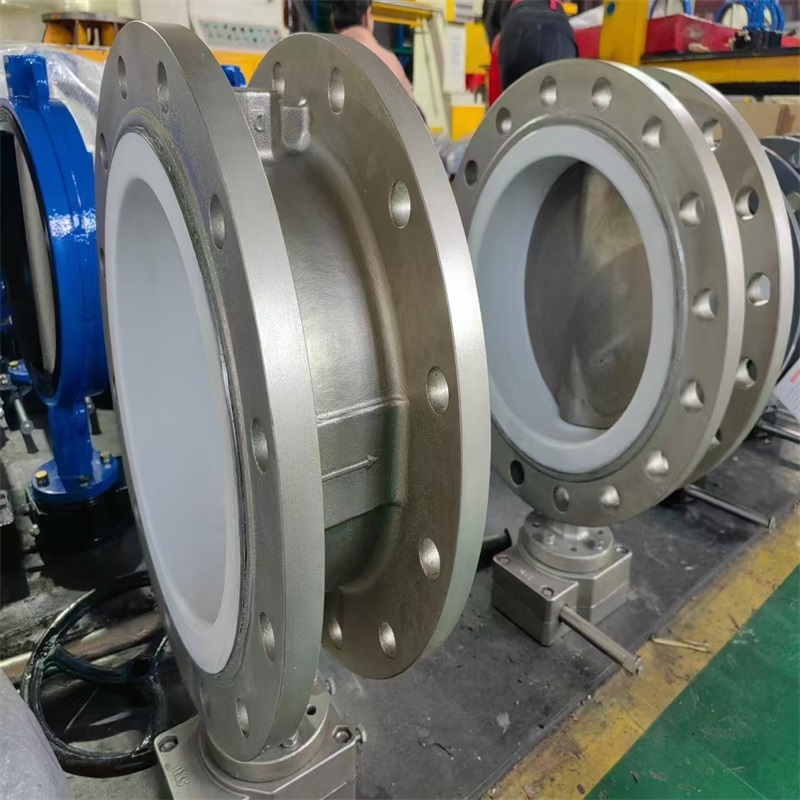

The stainless steel butterfly valve with dual flanges and PTFE (Polytetrafluoroethylene) lining is a versatile and robust fluid control device widely used in various industrial applications. Combining the durability of stainless steel with the non-stick properties of PTFE, this valve offers exceptional performance and reliability.

Paragraph 2: Material Composition

Constructed primarily from high-quality stainless steel, this valve ensures corrosion resistance and long-lasting durability. The valve’s disc, which is the moving part that controls fluid flow, is lined with PTFE. This lining not only enhances the valve’s sealing capabilities but also provides a smooth surface that reduces friction and wear.

Paragraph 3: Dual Flange Design

The dual flange design of this valve allows for easy installation and secure connection to piping systems. The flanges are typically welded or bolted to the valve body, ensuring a leak-tight seal. This design also facilitates maintenance and repair, as the valve can be easily disconnected from the piping system without disrupting the overall flow.

Paragraph 4: Operational Mechanism

The butterfly valve operates by rotating the PTFE-lined disc 90 degrees within the valve body. In the open position, the disc allows fluid to flow freely through the valve. When rotated to the closed position, the disc seals tightly against the valve seat, preventing fluid from passing. This simple and effective mechanism makes the valve highly efficient and reliable.

Paragraph 5: Applications

Due to its corrosion resistance, smooth operation, and ability to handle a wide range of fluids, this valve is ideal for use in chemical processing, food and beverage production, pharmaceutical manufacturing, and other industries where high-performance fluid control is crucial.

Paragraph 6: Conclusion

In conclusion, the stainless steel butterfly valve with dual flanges and PTFE lining is a superior choice for industrial fluid control applications. Its combination of durability, sealing performance, and ease of maintenance makes it an indispensable component in many industrial processes.