1. Sealing surface leakage

Cause of the fault:

Impurities are embedded in the sealing surface of the butterfly valve, the sealing surface is damaged, and the sealing surface is improperly installed, resulting in uneven force on the sealing surface. The seal is aged and damaged.

Solution:

Clean up the impurities on the sealing surface to ensure that the sealing surface is clean and flat.

Grind and repair the slightly damaged sealing surface. If the damage is more serious, a new seal needs to be replaced.

Reinstall the butterfly valve correctly to ensure that the installation position is accurate and the force is even. Check whether the pipeline connection is firm.

Replace aged and damaged seals.

2. The valve cannot be completely closed or opened

Cause of the fault:

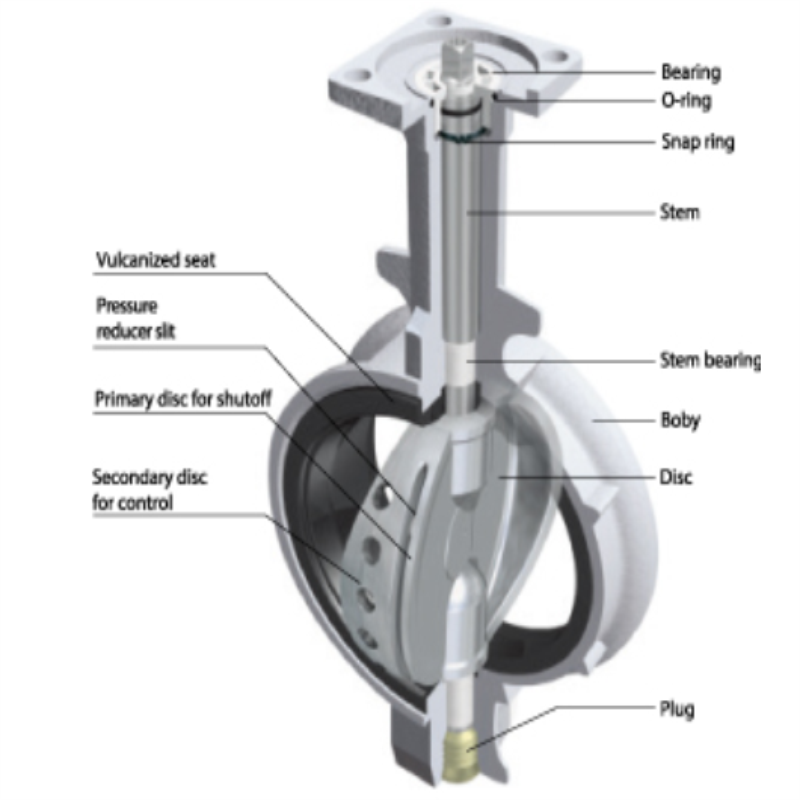

Foreign matter is stuck inside the butterfly valve, the valve stem is bent or deformed,

Drive device failure, such as motor damage of electric butterfly valve, air source problem of pneumatic butterfly valve, etc.

Solution:

Disassemble the butterfly valve and clean the foreign matter inside. Check the pipeline system to ensure that no other impurities enter.

Replace the bent or deformed valve stem. Ensure that it is firmly connected to the butterfly plate and is in the correct position.

Check the drive device, repair or replace damaged motors, air source components, etc.

3. Inflexible valve operation

Cause of failure:

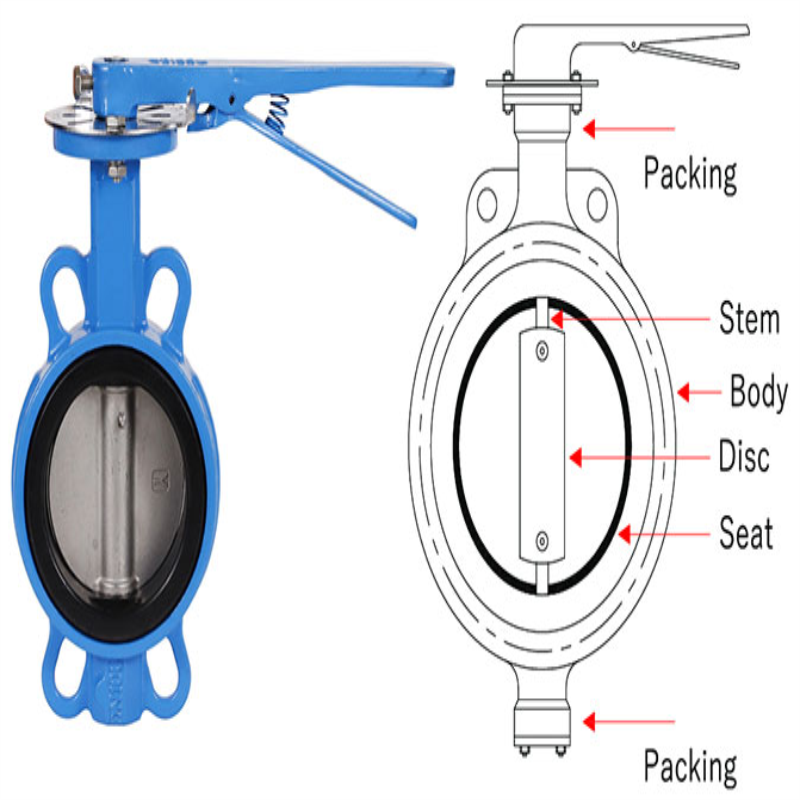

The friction between the valve stem and the packing is too large.

The butterfly valve has not been used for a long time, and the parts are rusted or corroded.

Operating mechanism failure, such as loose handle, gear wear, etc.

Solution:

Adjust the packing compression, add an appropriate amount of lubricant, and reduce the friction between the valve stem and the packing.

Derust and anti-corrosion treatment of rusted or corroded parts.

Repair or replace damaged parts of the operating mechanism. Ensure that the operating parts such as handles and gears can work normally.

4. Valve body leakage

Cause of the fault:

The valve body has cracks or sand holes.

The connecting bolts are loose, resulting in poor sealing.

Solution:

For valve bodies with cracks or sand holes, welding repair or replacement of new valve bodies is required. When selecting a valve body, ensure that its quality is reliable and meets relevant standards.

Tighten the connecting bolts to ensure that the valve body is tightly connected to the pipeline.