Wafer Type Butterfly Check Valve: Intelligent Protector in the Pipeline

In the complex industrial pipeline network, with its unique design and excellent performance, the wafer butterfly check valve has become an important device to ensure the unidirectional flow of fluids.

First, introduction

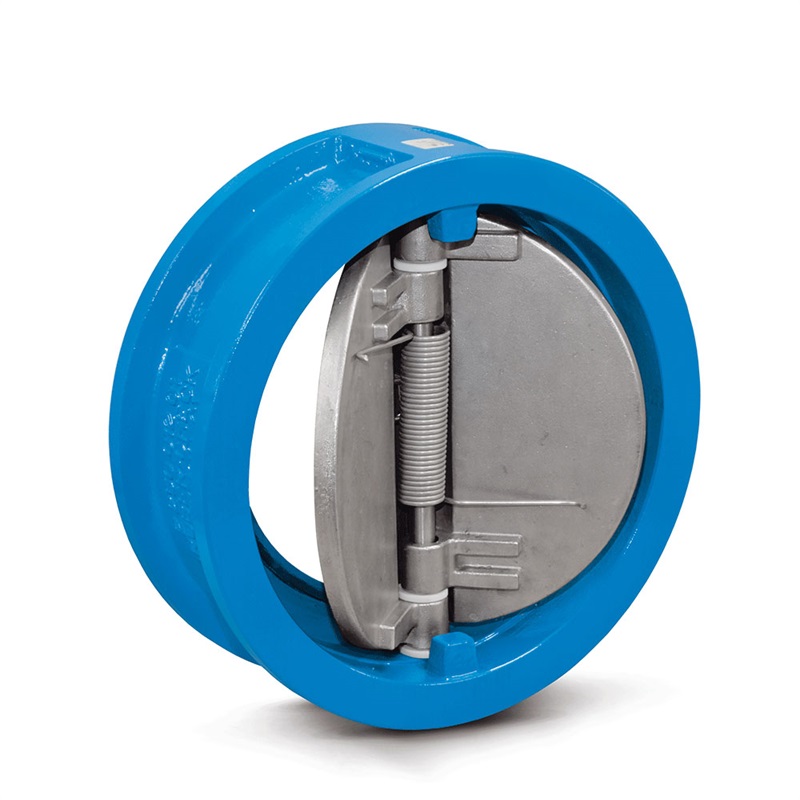

As an important member in the field of fluid control, the core function of the wafer butterfly check valve is to prevent the medium from flowing backwards in the pipeline, so as to protect the safe and stable operation of the system. Its unique dual-plate design and wafer connection makes it stand out among many check valves.

Second, the structure characteristics

The valve consists of valve body, double flaps, springs and connectors and other key components. The double flaps are connected by springs to achieve fast opening and closing. The clamped connection makes the installation easier, while the valve has a compact structure and light weight, which greatly saves the installation space and cost.

Third, the working principle

When the medium flows smoothly, the fluid pressure pushes the double flap to open, the medium can pass smoothly; once the medium stops flowing or reverse flow, the spring force quickly closes the valve flap, effectively preventing the medium from flowing backwards. This design not only improves the response speed of the valve, but also reduces the impact of water hammer on the piping system.

Fourth, advantages and applications

Wafer butterfly check valve has many advantages, such as rapid opening and closing, good sealing performance, low fluid resistance. These advantages make it widely used in petroleum, chemical, electric power, metallurgy and other industries, especially for high temperature, high pressure and corrosive media piping system. Its variety of materials to choose from, but also to meet the needs of different media on the corrosion resistance of the valve.

Fifth, installation and maintenance

The valve’s installation process is simple and quick, whether horizontal or vertical pipeline, can be easily installed. In terms of maintenance, due to its compact structure, parts replacement and overhaul is relatively easy. In addition, its long service life and high reliability also reduce the user’s maintenance costs.

Sixth, conclusion

With its unique structure, excellent performance and wide range of applications, the wafer double plate butterfly check valve has become an indispensable part of the piping system. In the future, with the continuous development of industrial technology, it is believed that the wafer butterfly check valve will be more intelligent and efficient, and provide a more solid guarantee for the safe and stable operation of pipeline system.