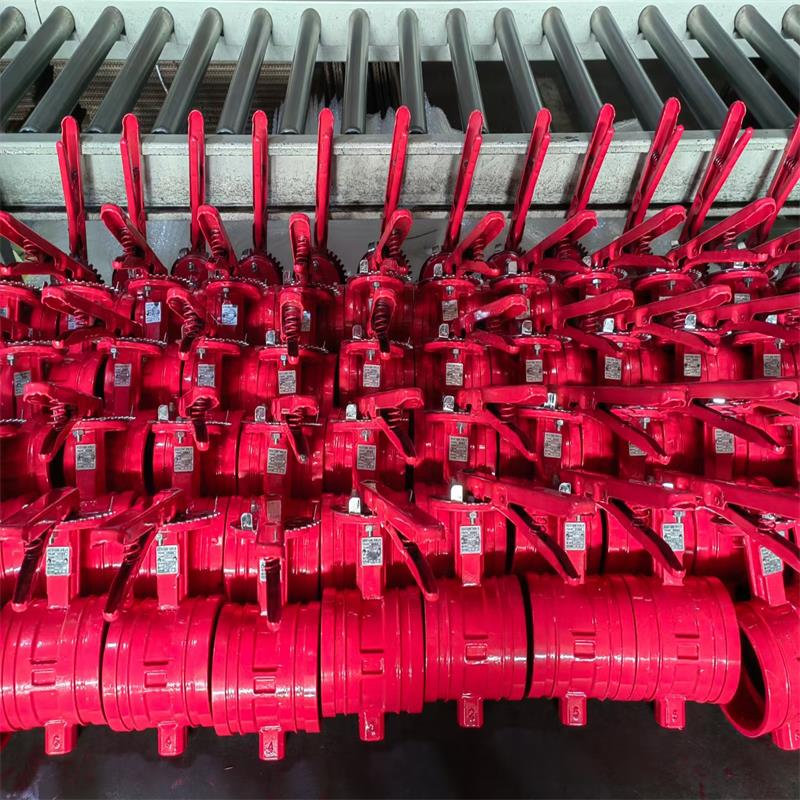

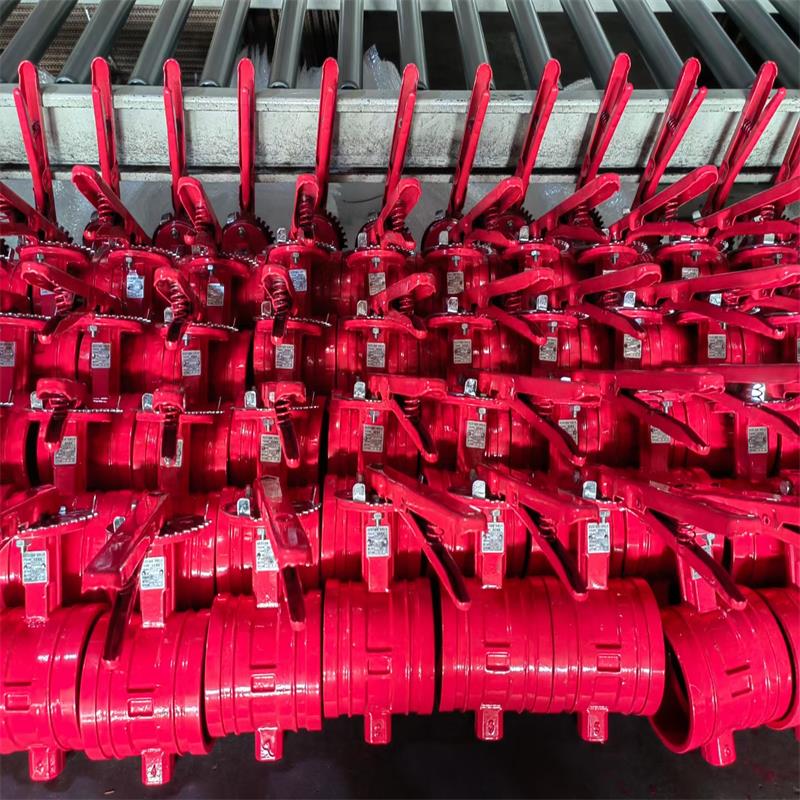

Groove Butterfly Valve: The Efficient Flow Controller in Modern Pipelines

The Groove Butterfly Valve is a versatile and efficient flow control device that has revolutionized the world of modern piping systems. Its unique design, incorporating grooved connections and a worm-driven mechanism, sets it apart as a preferred choice for various industrial applications.

The valve’s grooved ends facilitate easy and rapid installation, significantly reducing downtime and labor costs. This feature, coupled with its compact design, allows for seamless integration into existing piping infrastructure, regardless of size or complexity. The grooves also provide a secure and leak-proof connection, ensuring the integrity of the entire piping system.

At the heart of the Groove Butterfly Valve lies its worm-driven mechanism, which ensures smooth and precise control of fluid flow. The rapid rotation of the valve disc, driven by the worm-assisted actuator, allows for instantaneous adjustments to meet changing process requirements. This responsiveness makes it ideal for applications where flow rates need to be adjusted frequently or in emergency situations.

The valve’s construction, often featuring corrosion-resistant materials such as stainless steel and ductile iron, ensures long-term durability and reliability. Its ability to withstand extreme temperatures, pressures, and harsh chemicals makes it suitable for a wide range of industries, including oil and gas, petrochemicals, power generation, and water treatment.

In summary, the Groove Butterfly Valve is a highly efficient and versatile flow control solution for modern piping systems. Its innovative design, combined with its ease of installation, precise control capabilities, and durability, make it an invaluable asset for any industrial process. As industries continue to evolve and demand more from their piping systems, the worm Groove Butterfly Valve stands as a testament to the power of innovation and engineering excellence.