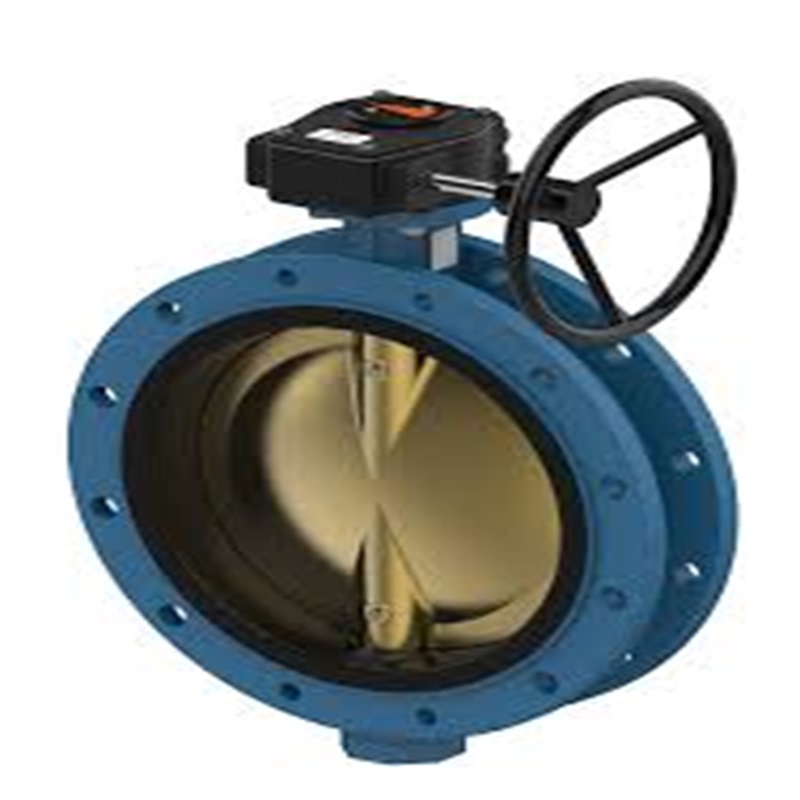

Butterfly valve flange dimension standards are typically selected based on the industry and international standards in use, covering various size ranges and parameters. Here are some specific details about butterfly valve flange dimension standards:

I. Size Range

The size range of butterfly valve flanges is extensive, encompassing various specifications from small to large. Common size standards include:

ANSI (American National Standards Institute): Widely applicable, with common sizes ranging from 2 inches to 60 inches.

DIN (Deutsches Institut für Normung): Primarily used in Europe and the Middle East, with common sizes from DN15 to DN1200.

JIS (Japanese Industrial Standards): Mainly used in Asia, with common sizes from 1/2 inch to 48 inches.

GB/T (General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China): Primarily used in China, with common sizes from DN15 to DN2400, though some sources indicate a range up to DN350~DN2600.

II. Specific Parameters

The specific dimensional parameters of butterfly valve flanges include nominal diameter (DN), nominal pressure (PN), flange connection dimensions, bolt hole sizes, etc.

Nominal Diameter (DN): Indicates the diameter of the fluid pipeline that the valve can accommodate, as mentioned above.

Nominal Pressure (PN): Indicates the maximum pressure the flange butterfly valve can withstand during operation, with common ranges from PN6 to PN16, and some standards extending to higher pressure ratings like PN100.

III. Flange Connection Dimensions

Flange connection dimensions are a crucial part of butterfly valve flange dimension standards, encompassing pipe diameter range, hole diameter range, gasket thickness, gasket shape, gasket size, connection dimensions, bolt hole positions, flange sealing dimensions, etc. These dimensions are detailed in relevant standards and specifications such as GB/T 9113-2000, ANSI B16.5, DIN 2501, and JIS B2220.

IV. Other Considerations

Butterfly valve flange dimension standards may vary depending on the manufacturer and specific application scenario.

When selecting and using butterfly valve flanges, refer to the technical specifications of the specific product or consult the manufacturer to ensure compliance with actual needs and relevant standards.

Regular maintenance and upkeep of butterfly valve flanges are necessary to ensure their proper operation and extended service life.

In summary, butterfly valve flange dimension standards constitute a complex and diverse system encompassing various dimensions and parameters. In practical applications, selection and use should be based on specific requirements and standard specifications.