A pneumatic butterfly valve is a type of valve that utilizes pneumatic devices to control its opening and closing. Here’s a simplified breakdown of its control principle:

1.Compressed Air Supply: The pneumatic butterfly valve requires compressed air from an air source, typically operating at a pressure range of 0.4-0.8MPa.

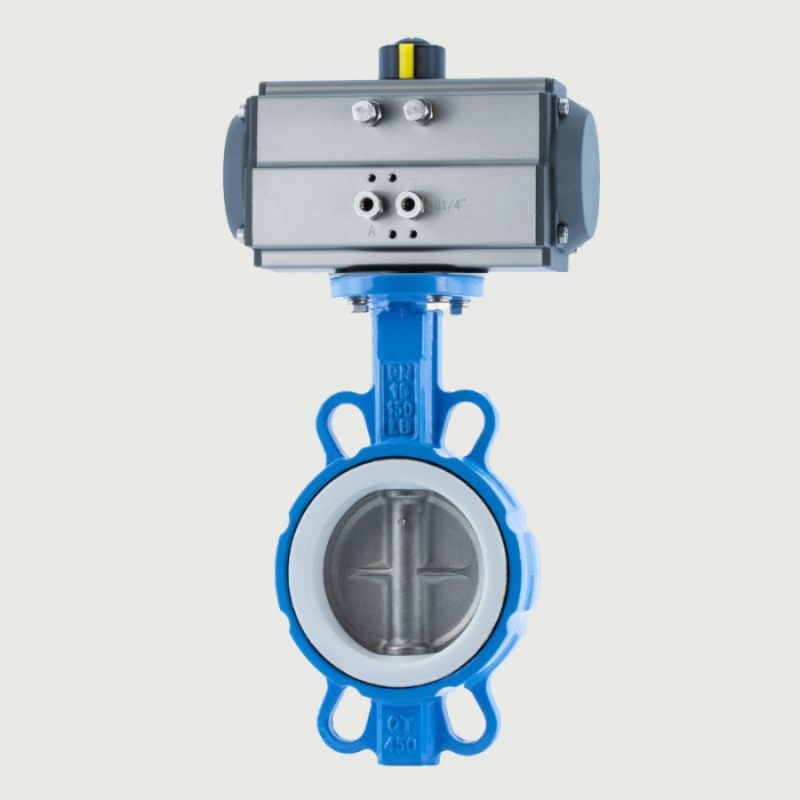

2.Pneumatic Device: The pneumatic device of the valve comprises mainly a pneumatic actuator and an air source. The actuator, often a pneumatic-driven piston, is actuated by the compressed air supplied by the air source.

3.Control Signal: The opening and closing of the pneumatic butterfly valve are achieved through a control signal. This signal can be pneumatic or electrical in nature.

4.Control Mechanism: Typically, the control mechanism is a pneumatic valve that regulates the flow of air to the pneumatic actuator. By controlling the opening and closing of the gas flow, it manipulates the actuator.

5.Opening and Closing Process: When a control signal is input to the pneumatic valve, it opens a pathway, allowing compressed air to enter the pneumatic actuator. This drives the piston forward, opening the butterfly valve. Conversely, when the control signal is terminated, the pneumatic valve closes the pathway, releasing compressed air from the actuator. The piston moves backward, closing the butterfly valve.

6.Feedback Signal: Some pneumatic butterfly valves are equipped with a feedback signal device. This device senses the valve’s position and sends a signal back to the control system, enabling precise control and adjustment of the valve.

In summary, the pneumatic butterfly valve converts control signals into pneumatic force through its pneumatic device, thereby controlling the opening and closing of the valve for fluid regulation and control.