In the modern industrial field, valves are indispensable key components in fluid control systems, and their performance and stability are directly related to the smoothness and safety of the entire production process. Among them, double-acting pneumatic stainless steel ball valves with positioners have been widely used in many industries such as petroleum, chemical, electric power, papermaking, metallurgy, etc. due to their unique advantages.

1. Product Overview

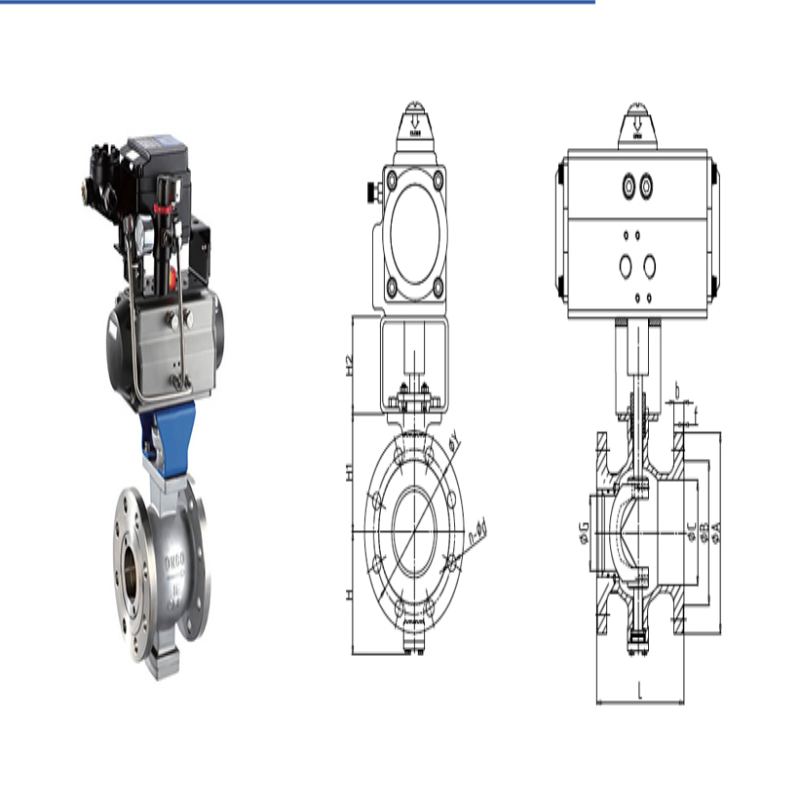

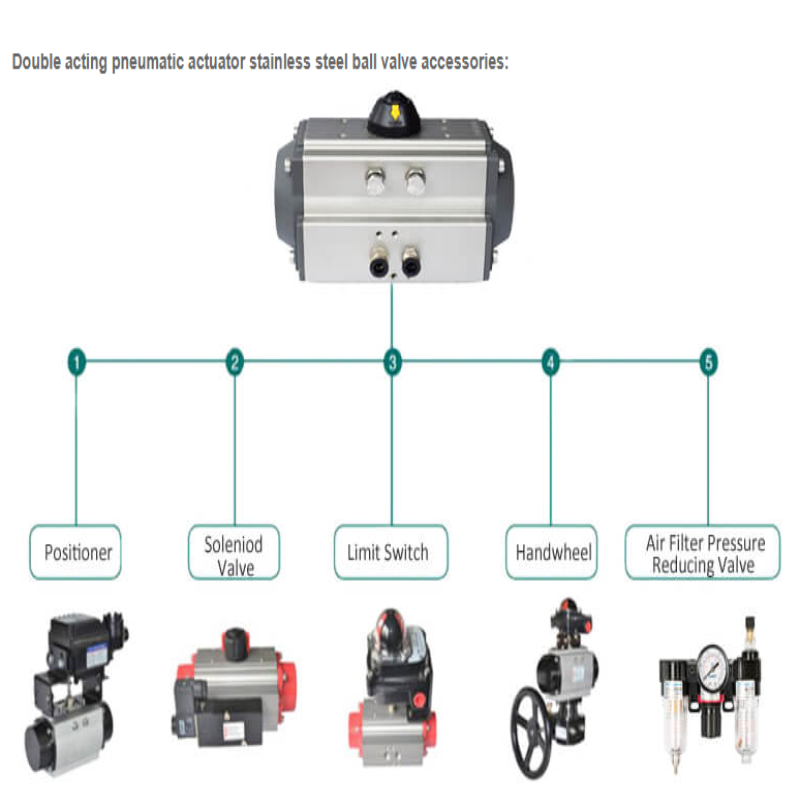

Double-acting pneumatic stainless steel ball valve with positioner is an intelligent control valve that integrates pneumatic actuators, stainless steel ball valve bodies and positioner accessories. The valve drives the rotation of the ball valve through a double-acting pneumatic actuator to realize the on-off and regulation functions of the fluid. At the same time, with the precise control of the positioner, it can achieve precise adjustment of the valve opening to meet the precise control requirements under complex working conditions.

2. Working principle

The working principle of the double-acting pneumatic stainless steel ball valve with positioner is relatively complex but efficient. When the control system sends a control signal, the positioner first receives and analyzes the signal, and calculates the required air source pressure value according to the preset control logic. Subsequently, the solenoid valve controls the on and off of the gas circuit, and the air source of the corresponding pressure is sent to the left and right air chambers of the cylinder piston respectively. Due to the different air source pressures of the left and right air chambers, a pressure difference is formed, which pushes the piston to move linearly. The movement of the piston is converted into the rotational movement of the valve stem through the gear rack transmission mechanism, which in turn drives the ball to rotate 90 degrees to achieve the opening and closing or adjustment of the valve.

3. Technical features

High reliability: The valve body and ball made of stainless steel have good corrosion resistance and mechanical strength, ensuring the long-term stable operation of the valve under harsh working conditions.

Easy maintenance: The valve has a compact structure and modular design of components, which is easy to disassemble and replace. At the same time, the intelligent design of accessories such as positioners also simplifies the maintenance workflow.

4. Application scenarios

Power industry: In the power system, it is necessary to effectively control mediums such as high-temperature and high-pressure steam. Double-acting pneumatic stainless steel ball valve with positioner can withstand high temperature and high pressure environment to ensure the safe and stable operation of the power system.

Metallurgical industry: In the metallurgical process, various metal melts need to be precisely controlled. Double-acting pneumatic stainless steel ball valve with positioner has been widely used in the metallurgical industry with its excellent high temperature resistance and precise control capabilities.

5. Summary

In summary, the double-acting pneumatic stainless steel ball valve with positioner has become an indispensable and important equipment in the field of modern industrial fluid control.